Application Technology

Understand cutting-edge application technology

Application Technology

Platinum group metals have been grinding for a decade, and the future is not to be underestimated

- Categories:Application Technology

- Author:

- Origin:

- Time of issue:2022-10-20 09:09

- Views:0

(Summary description)As the "newborn" of the metal family, platinum group precious metals play an indispensable role from the transformation of the traditional petrochemical industry to the whole industrial chain of new energy, including hydrogen energy, and will eventually play an important role in the development of the 21st century!

Platinum group metals have been grinding for a decade, and the future is not to be underestimated

(Summary description)As the "newborn" of the metal family, platinum group precious metals play an indispensable role from the transformation of the traditional petrochemical industry to the whole industrial chain of new energy, including hydrogen energy, and will eventually play an important role in the development of the 21st century!

- Categories:Application Technology

- Author:

- Origin:

- Time of issue:2022-10-20 09:09

- Views:0

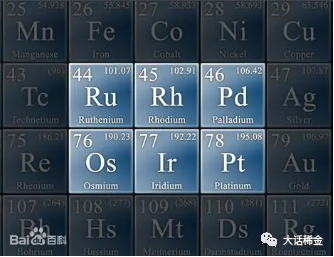

Platinum series metals belong to the periodic group Ⅷ elements, also known as platinum series, rare metals, including platinum (Pt), palladium (Pd), osmium (Os), Iridium (Ir), Ruthenium (Ru), rhodium (Rh) six metals.

Platinum series metals belong to the periodic group Ⅷ elements, also known as platinum series, rare metals, including platinum (Pt), palladium (Pd), osmium (Os), Iridium (Ir), Ruthenium (Ru), rhodium (Rh) six metals.

The Shanghai Platinum Week and China Platinum Group Metals Market Summit in September 2022 brought the latest research and development reports in the fields of hydrogen energy and fuel cells, electronic materials, medicine and health, petrochemicals, energy conservation and environmental protection, additive manufacturing, artificial intelligence, etc. Platinum group metals are about to usher in a wave of industrial boom.

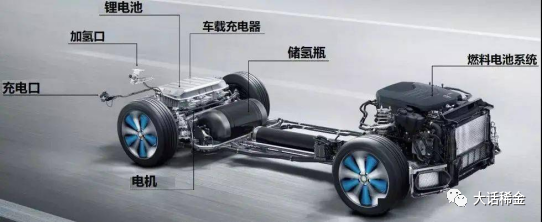

Hydrogen energy and fuel cells

In recent years, affected by the fluctuation of international crude oil prices, domestic oil prices have risen, and the cost of using traditional fuel vehicles has risen. New energy vehicles began to occupy the market in response to the implementation of the two-carbon policy and the rise in gasoline prices. As the "vitamin" of new energy and new materials industry, platinum is increasingly important in the application of new energy vehicle industry.

With the acceleration of the decarbonization process of the world's energy structure, the market demand for platinum group metals to keep up with new energy vehicles will be further enhanced. There is a high demand for platinum group precious metals in the fields of renewable energy, energy storage, power grid peak regulating and hydrogenation integrated stations.

Breakthroughs have been made in artificial vision

A memristor driven by light has been developed in the world, which can be used to build a new generation of artificial vision system. The device is fabricated based on oxide semiconductors and platinum group metals, and its unique all-optical control performance is attributed to the large work function and excellent chemical stability of platinum group metals. It is expected that the emergence of all-optical memristor will break the barrier of the application of integrated sensory/memory/computing artificial vision systems, which will enter our daily life in the near future.

Opportunities and challenges of platinum group metals in pharmaceutical industry

Platinum nanomaterials and platinum-based alloys have unique advantages such as high sensitivity, low specificity and high catalytic efficiency, which have broad application prospects in the medical in vitro detection and diagnosis market. The large-scale application of these materials provides an opportunity to accelerate the construction of a national health care system for early detection, early diagnosis and early treatment.

Treatment of highly polluted wastewater by catalytic oxidation

Green low-carbon CWAO technology based on multiphase platinumruthenium catalysts can simultaneously remove organic carbon and ammonia nitrogen compounds, which is expected to be a sustainable and efficient solution for the treatment of highly concentrated organic wastewater in coking, dye, pesticide, petrochemical and other industries.

VOC catalyst for volatile organic compounds

Precious metal subnano cluster coupling photocatalyst, industrial exhaust purification and deodorization market of 10 billion, is expected to create new sustainable value for the domestic environmental protection industry.

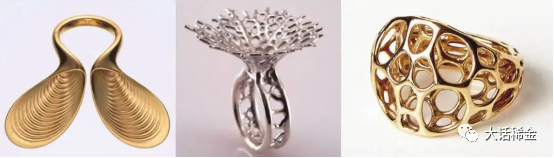

Add material manufacture

The new economy innovation of platinum group precious metals in accessories, industry, chemicals, healthcare and other fields has the potential to usher in a new era through the combination of additive manufacturing and digital design innovation, Address the long-term challenges faced by today's subtractive manufacturing processes, such as product structure complexity, technical process instability, minimum production lot requirements, high rate of change in consumer trends, and intellectual property protection in digital design.

At present, hydrogen energy is indeed a rapidly developing industry. It is speeding up its development towards large-scale hydrogen production equipment of 1400 to 3000 standard meters, high efficiency and low energy consumption, and adapting to the unstable, volatile and intermittent characteristics of renewable energy. In particular, in alkaline electrolysis, precious metals have now become essential materials. With the support of Anglo American and China, experiments and innovations using precious metal electrodes have begun, and the hydrogen production equipment market is expected to grow from 800 million to 800 billion in the next decade.

As the "newborn" of the metal family, platinum group precious metals play an indispensable role from the transformation of the traditional petrochemical industry to the whole industrial chain of new energy, including hydrogen energy, and will eventually play an important role in the development of the 21st century!

Scan the QR code to read on your phone

Hot Technology Ranking

2022-10-20

Scan the QR code and follow the official account

Products

Precious metal functional materials

High-quality optoelectronic materials/high-purity targets

Refractory metals and their alloys

Special alloy/special steel

Spherical | Nano powder

Biomedical/3D printing products

Compound

Rare metals and their alloys

Rare metals and their alloysRare Metal Concept Cultural/Art/Collectible

Nuclear energy Nuclear power Nuclear industry

High temperature heat container

Microelectronics industry Chip thermal sink

Semiconductor equipment MOCVD thermal field

High efficiency & long life Wire for wire cutting

Medical equipment Medical instruments

Artificial bone joint Bioimplantation

Rare metal cultural & creative art collection Precious metal

Plasma|Special Welding Electrode

Ultra Minor Metals Ltd (UMM) all rights reserved 湘ICP备17001881号 by:www.300.cnchangsha