首页

Solutions

UMM Professional provides suitable solutions for all walks of life

Products

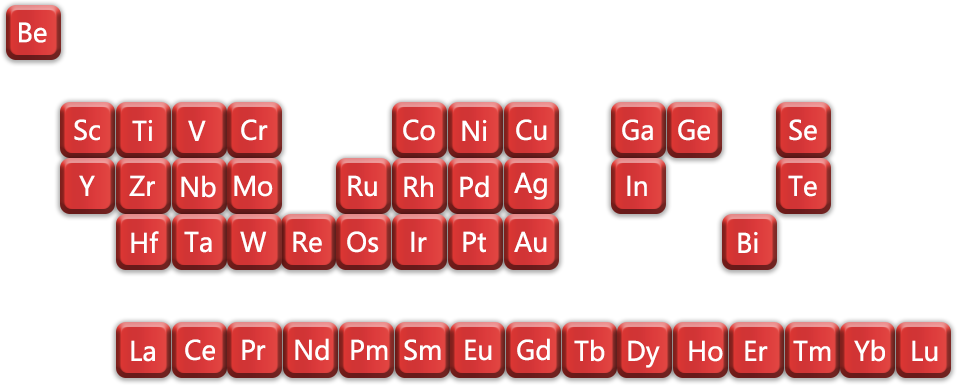

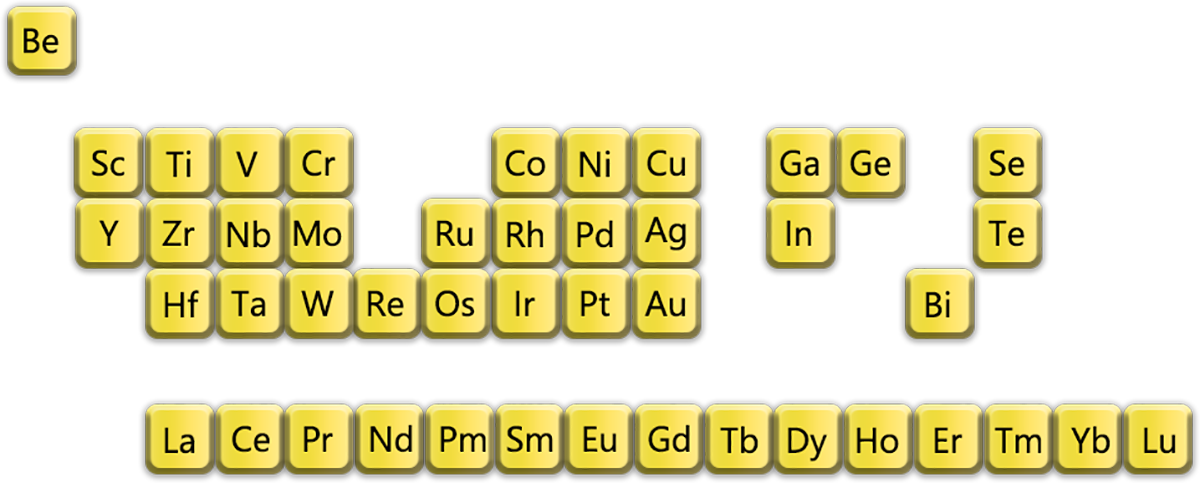

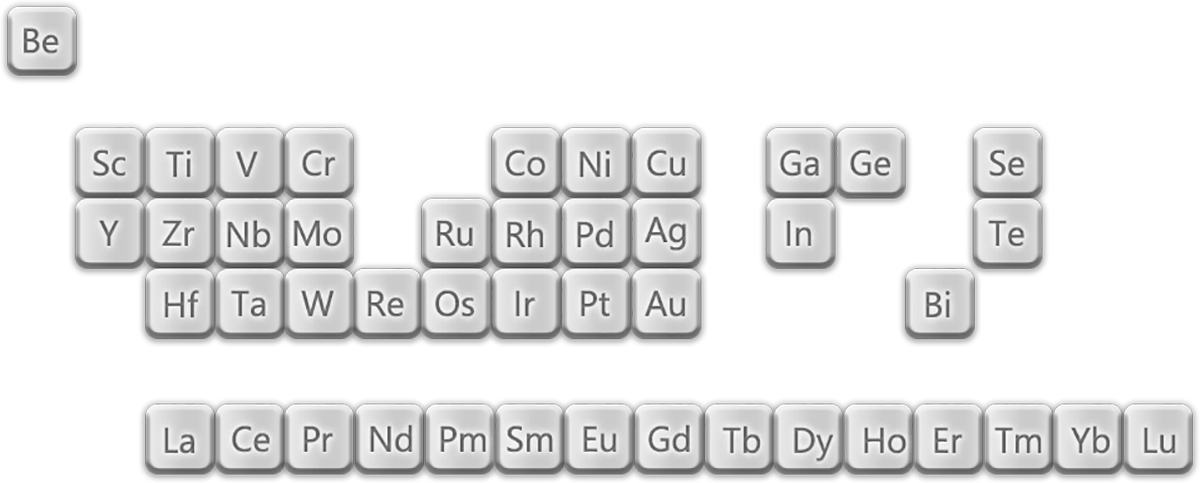

Ten sectors of high-end specialty rare-material products Specializing in the production of rares metals and finished products

-

+

查看更多- High-quality optoelectronic materials/high-purity targets

- MOCVD heating parts

- Sputtering target

- High purity metal

- Evaporation materials

- Heat sink material

- Ion implant

Contains MOCVD heating parts, High-performance sputtering target, High purity metal Evaporation materials, rhenium target, Os sputtering target, Ru sputtering target, Ta sputtering target, Tantalum target, Ir sputtering target, tungsten titanium target, ruthenium target, osmium target, nickel chromium target, Iridium target, sputtering target, Tungsten target, Titanium Target, etc. -

+

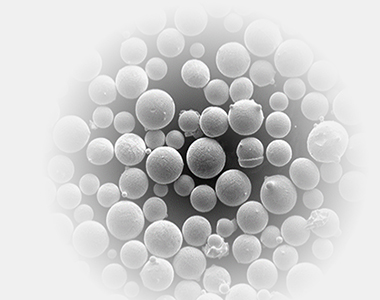

查看更多- Powder metallurgy intermediate products & Special powder

- Spherical powder

- Nano powder

- Powder metallurgy intermediate products

Including nano powder materials (ultra-fine powder or ultra-fine powder, generally refers to powder or powder with a particle size of less than 100 nanometers); spherical powder (mainly used for 3D printing, precision additive manufacturing)

Application Technology

Understand cutting-edge application technology

Overview of Vacuum Ion Coating

Overview of Chemical Vapor Deposition (CVD) Coating

Overview of Evaporative Coating and Its Material Selection

Founded in 2009

Total investment

Construction area

Technology invention patent

Industry News

Learn more about us through the industry

2024

07 26

2024

07 23

2024

07 20

2024

07 17

Quick Navigation

Click to quickly learn about popular products and solutions

Products

Precious metal functional materials

High-quality optoelectronic materials/high-purity targets

Refractory metals and their alloys

Special alloy/special steel

Spherical | Nano powder

Biomedical/3D printing products

Compound

Rare metals and their alloys

Rare metals and their alloysRare Metal Concept Cultural/Art/Collectible

Nuclear energy Nuclear power Nuclear industry

High temperature heat container

Microelectronics industry Chip thermal sink

Semiconductor equipment MOCVD thermal field

High efficiency & long life Wire for wire cutting

Medical equipment Medical instruments

Artificial bone joint Bioimplantation

Rare metal cultural & creative art collection Precious metal

Plasma|Special Welding Electrode

Ultra Minor Metals Ltd (UMM) all rights reserved 湘ICP备17001881号 by:www.300.cnchangsha