Products Center

Top ten high-end specialty thin material products

Products

Application:

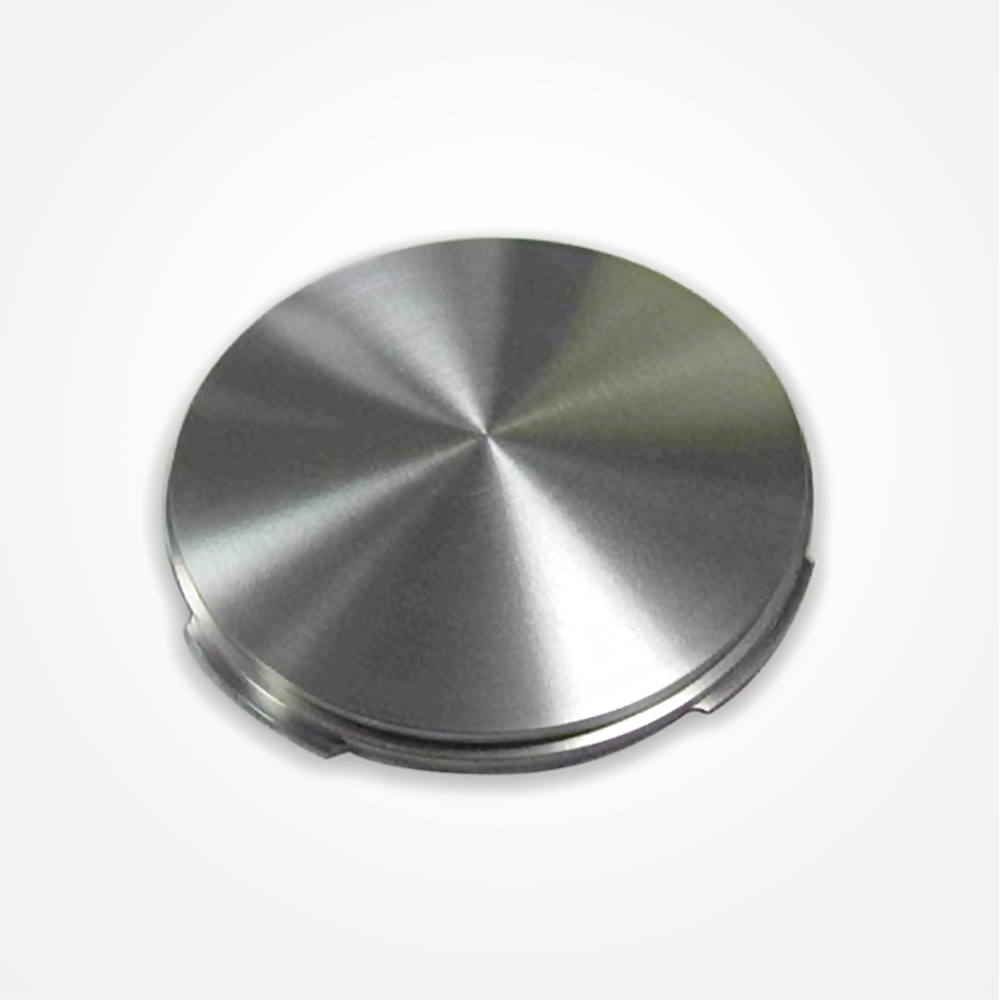

High-purity tungsten targets, high-purity tungsten-titanium alloy targets, and tungsten-silicon composite targets are usually applied by magnetron sputtering to produce various complex and high-performance thin film materials. Because high-purity tungsten or ultra-pure tungsten (5 N or 6 N) has high resistance to electron migration, high temperature stability, and the ability to form stable silicides, it is often used as a thin film in the electronics industry as a gate, connection, transition and Barrier metal. Ultra-high-purity tungsten and its silicides are also used in ultra-large-scale integrated circuits as resistance layers, diffusion barriers, etc., and as gate materials and connection materials in metal oxide semiconductor transistors. Tungsten-titanium alloy sputtering targets are often used to make transition metal layers of thin-film solar cells.

Specification:

|

Name |

Molecular formula | Specification |

Size |

Relative density | Grain size | Defect rate | |

| Tungsten target |

W |

4N(99.99%) |

Inch |

mm |

≥99% |

≯50µm |

0 |

|

5N(99.999%) |

D(2,3,4,6,8,10,12) H(0.25,0.5,0.75) |

Diameter 50~350 Thickness 6~25 |

|||||

| Tungsten Titanium Target |

WTi10 WTi20 |

4N(99.99%) |

≥99% |

≯50µm |

0 |

||

|

4N5(99.995%) |

|||||||

Chemical Composition

|

Specification grade Chemical index |

W/(W+Ti)≥99.99% |

W/(W+Ti)≥99.995% |

W≥99.999% |

|||||||||

| Total trace impurities |

≯100 ppm |

≯50 ppm |

≯10 ppm |

|||||||||

|

Impurity index(ppm) |

Max |

Typical value | Max | Typical value | Max | Typical value | ||||||

|

Radioactive elements |

U |

— |

0.2 |

0.1 |

0.05 |

0.0008 |

0.0005 |

|||||

|

Th |

— |

0.2 |

0.1 |

0.05 |

0.0008 |

0.0005 |

||||||

|

Alkali metal elements |

Li |

1 |

0.05 |

0.02 |

0.01 |

0.01 |

0.003 |

|||||

|

Na |

5 |

1 |

0.5 |

0.2 |

0.1 |

0.05 |

||||||

|

K |

5 |

1 |

0.1 |

0.05 |

0.05 |

0.03 |

||||||

|

Mo,Re |

10 |

5 |

10 |

5 |

1 |

0.5 |

||||||

|

Fe,Cr |

10 |

5 |

5 |

3 |

0.5 |

0.3 |

||||||

|

Ca,Si,Cu,Ni,Al,Zn,Sn,Mn,Co,Hg,V |

2 |

1 |

0.5 |

0.3 |

0.2 |

0.2 |

||||||

|

P,As,Se |

2 |

1 |

0.5 |

0.2 |

0.2 |

0.2 |

||||||

|

B,Pb,Sb,Be,Ba,Bi,Cd,Ge,Nb,Pt,Mg,Zr,Au,In,Ga,Ag |

1 |

0.5 |

0.5 |

0.1 |

0.1 |

0.1 |

||||||

| All other individual elements |

1 |

0.5 |

0.5 |

0.1 |

0.1 |

0.1 |

||||||

|

Gas analysis (≯,ppm) |

O |

C |

N |

H |

S |

|||||||

|

500 |

20 |

20 |

20 |

10 |

||||||||

Depending on the purpose of use, there are different requirements for the impurity content of high-purity tungsten targets and tungsten-titanium targets. Generally, the chemical purity is required to be between 99.99% and 99.999%. We can also customize other specifications suitable for the application according to user requirements.

Everyone is watching

Products

Precious metal functional materials

High-quality optoelectronic materials/high-purity targets

Refractory metals and their alloys

Special alloy/special steel

Spherical | Nano powder

Biomedical/3D printing products

Compound

Rare metals and their alloys

Rare metals and their alloysRare Metal Concept Cultural/Art/Collectible

Nuclear energy Nuclear power Nuclear industry

High temperature heat container

Microelectronics industry Chip thermal sink

Semiconductor equipment MOCVD thermal field

High efficiency & long life Wire for wire cutting

Medical equipment Medical instruments

Artificial bone joint Bioimplantation

Rare metal cultural & creative art collection Precious metal

Plasma|Special Welding Electrode

Ultra Minor Metals Ltd (UMM) all rights reserved 湘ICP备17001881号 by:www.300.cnchangsha