Products Center

Top ten high-end specialty thin material products

Products

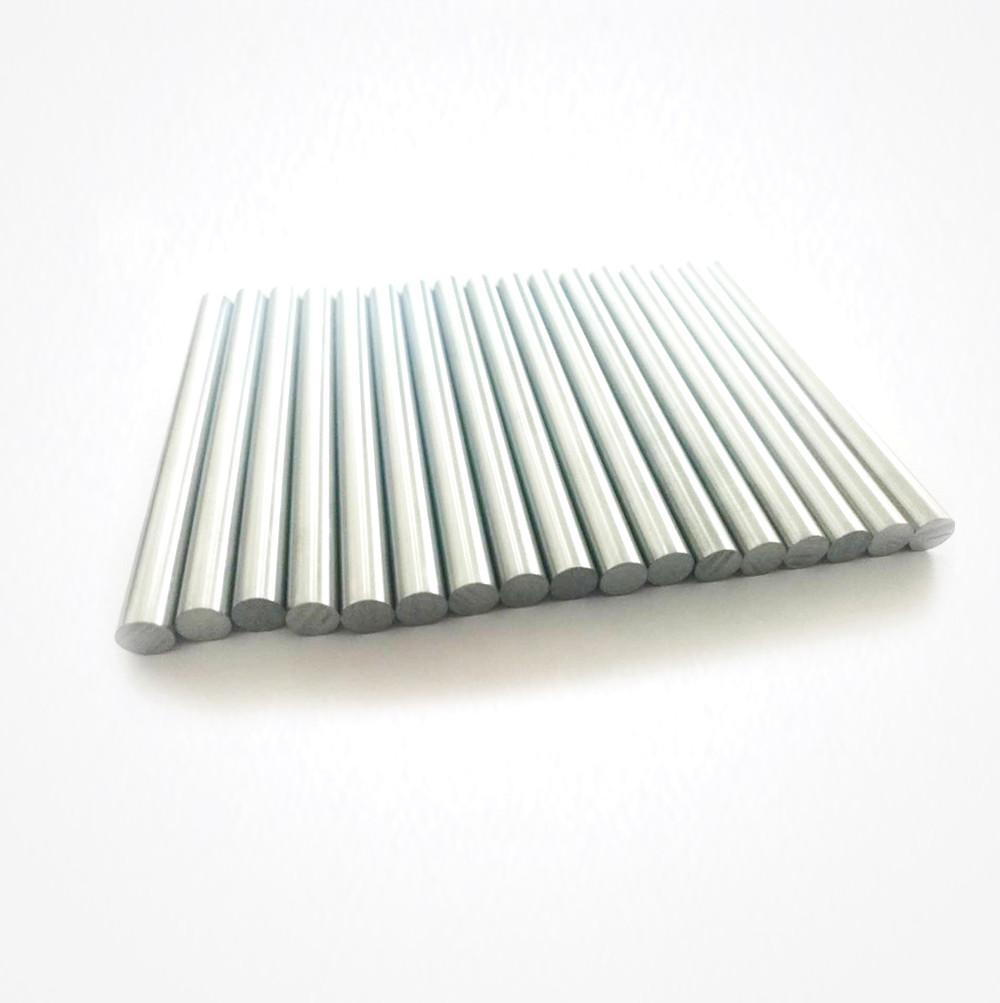

Diameter:φ1~φ17mm

Mo-Re alloy is Molybdenum Alloyed with 41% or 47.5% of Rhenium(nominal content of Rhenium is 50%), which has good ductility, weld ability, formability and strength. Mo-Re alloy keeps high ductile even after used in high temperature. Mo-Re alloy are widely used for electronics, nuclear and aerospace applications.

|

Product Name |

Main Type |

Main Spec.(mm) |

|

Mo-Re Alloy Wire |

MoRe14% MoRe41%, MoRe44.5%, |

φ0.1,φ0.2,φ0.25,φ0.3,φ0.35,φ0.5 |

|

Mo-Re Alloy Rod/Bar |

φ1~φ17 |

|

|

Mo-Re Alloy Plate |

0.2 min.×(10-500)×1000 max. |

|

|

Mo-Re Alloy Target |

Customized as per requirement |

|

|

Mo-Re Alloy Tube |

Note: other models and specifications can be customized by agreement.

Everyone is watching

Products

Precious metal functional materials

High-quality optoelectronic materials/high-purity targets

Refractory metals and their alloys

Special alloy/special steel

Spherical | Nano powder

Biomedical/3D printing products

Compound

Rare metals and their alloys

Rare metals and their alloysRare Metal Concept Cultural/Art/Collectible

Nuclear energy Nuclear power Nuclear industry

High temperature heat container

Microelectronics industry Chip thermal sink

Semiconductor equipment MOCVD thermal field

High efficiency & long life Wire for wire cutting

Medical equipment Medical instruments

Artificial bone joint Bioimplantation

Rare metal cultural & creative art collection Precious metal

Plasma|Special Welding Electrode

Ultra Minor Metals Ltd (UMM) all rights reserved 湘ICP备17001881号 by:www.300.cnchangsha