Industry News

Learn more about us through the industry

News

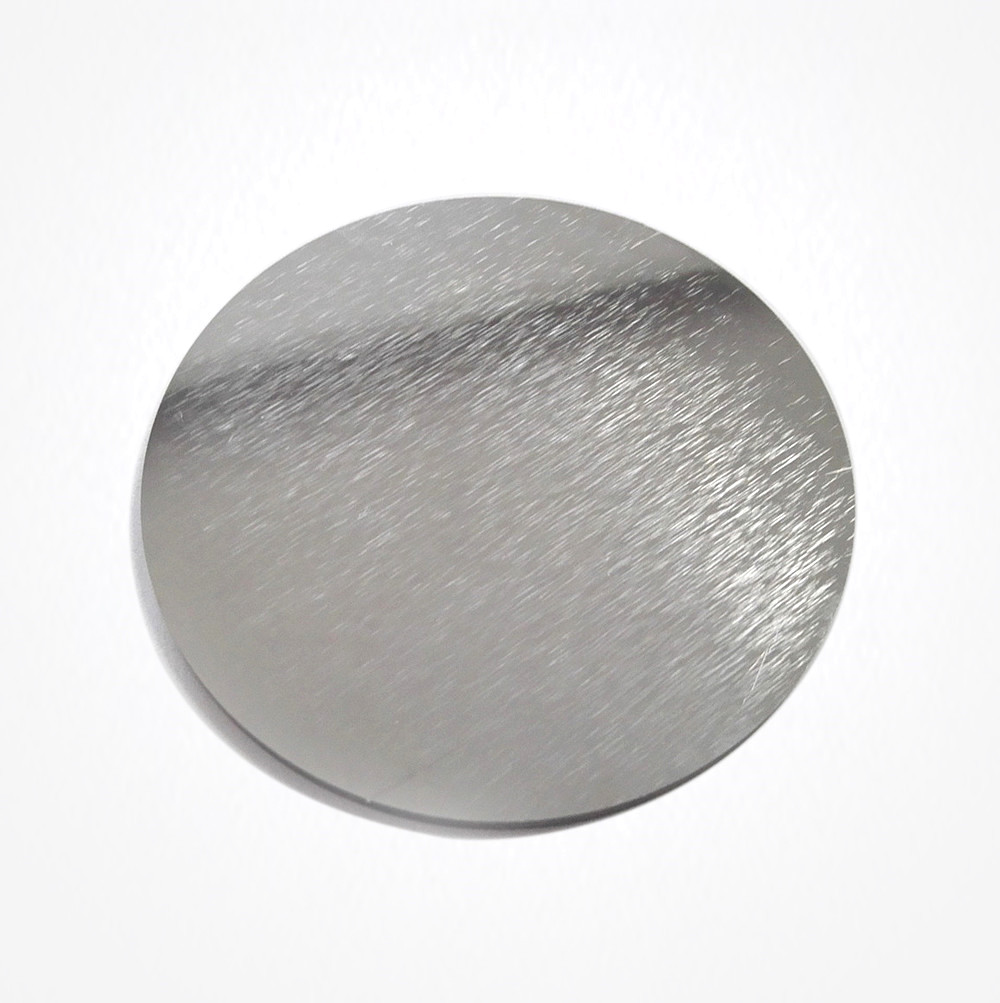

Application of rhenium target in sputtering coating

- Categories:rhenium target news

- Author:

- Origin:

- Time of issue:2021-07-22 18:08

- Views:0

(Summary description)This article briefly introduces the application of rhenium target

Application of rhenium target in sputtering coating

(Summary description)This article briefly introduces the application of rhenium target

- Categories:rhenium target news

- Author:

- Origin:

- Time of issue:2021-07-22 18:08

- Views:0

Rhenium target is used for magnetron sputtering coating. Magnetron sputtering coating is a new type of physical vapor phase (PVD) coating. Compared with evaporation coating, it has considerable advantages in many aspects. As a mature technology, magnetron sputtering has been applied in many fields, such as semiconductor integrated circuits, solar photovoltaic, recording media, and so on.Planar display and workpiece surface coating are widely used.

Sputter coating is a technology that makes the bombarded particles deposit on Rhenium target by bombarding the target surface with energetic particles in vacuum.In general, incoming ions are generated by glow discharge of low-pressure inert gases.

The cathode target is made of coated material, and rhenium target is used as the anode. Argon or other inert gases of 0.1-10 Pa are introduced into the vacuum chamber. Glow discharge is generated when the cathode (target) is subjected to negative DC voltage of 1-3 KV or radio frequency voltage of 13.56 MHz.The ionized argon ion bombards the surface of the target, causing the target atoms to splash and deposit on the rhenium target, forming a thin film.

There are many sputtering methods, such as secondary sputtering, third or fourth sputtering, magnetron sputtering, target sputtering, radio frequency sputtering, bias sputtering, asymmetric AC radio frequency sputtering, ion beam sputtering and reactive sputtering.

Because the sputtered atoms are splashed with positive ion exchange kinetic energy of tens of electron volts, the splashed atoms have a high energy, which is helpful to improve the diffusion ability of atoms during deposition, to improve the compactness of deposited tissues, and to make the films have a strong adhesion with rhenium target.

When sputtering, after the gas is ionized, the gas ions fly to the target that connects the cathode under the action of the electric field, while the electrons fly to the grounded wall cavity and substrate.Thus, at low voltage and low pressure, the number of ions produced is small and the sputtering efficiency of the target is low.At high voltage and pressure, although more ions can be produced, electrons flying to rhenium target carry high energy, which makes rhenium target heat easily and even secondary sputtering, which affects the quality of the film.

In addition, the probability of collision between target atoms and gas molecules during the flight to rhenium target is greatly increased. As a result, the target atoms are scattered throughout the cavity, which will result in waste of target materials and pollution of all layers in the preparation of multilayers.

Scan the QR code to read on your phone

Top dynamic rankings

Scan the QR code and follow the official account

Products

Precious metal functional materials

High-quality optoelectronic materials/high-purity targets

Refractory metals and their alloys

Special alloy/special steel

Spherical | Nano powder

Biomedical/3D printing products

Compound

Rare metals and their alloys

Rare metals and their alloysRare Metal Concept Cultural/Art/Collectible

Nuclear energy Nuclear power Nuclear industry

High temperature heat container

Microelectronics industry Chip thermal sink

Semiconductor equipment MOCVD thermal field

High efficiency & long life Wire for wire cutting

Medical equipment Medical instruments

Artificial bone joint Bioimplantation

Rare metal cultural & creative art collection Precious metal

Plasma|Special Welding Electrode

Ultra Minor Metals Ltd (UMM) all rights reserved 湘ICP备17001881号 by:www.300.cnchangsha