Alloy addition solution

UMM provides high-purity elemental metals or master alloys with purity ranging from 99.9% to 99.9999% (3N~6N) to major alloy manufacturing industries. As alloy additives, its chemical purity is the key to ensuring the accuracy of alloy composition and improving the yield rate. factor. Therefore, based on the same national standard or industry standard, UMM through the combined application of wet purification and fire refining technology, as well as more accurate high-purity metal detection methods, can always ensure that its products are far beyond the national standard and the industry standard. Quality and performance.

Material solutions in the aerospace industry

Rheniumet, a subsidiary of UMM, has excellent mechanical properties even at high temperatures of 2000 ℃ due to its alloy pure rhenium or rhenium-based superalloys, so it is used in the fields of aviation, aerospace, and space science for high temperature and high strength in thermodynamic drive devices. Almost all parts have rhenium. The thrust-to-weight ratio of aero-engines continues to increase, and the technical performance requirements for engine turbine blade materials are also continuously improved. The successful development and large-scale application of nickel-based rhenium-containing superalloys (with rhenium 2%-7%) have become large-scale aviation vehicles. The trend of modernization and high-speed development provides the most important material guarantee.

Material solutions for nuclear energy, nuclear power, and nuclear industry

UMM provides rhenium, tungsten, platinum, molybdenum and other alloys that can be made into a series of high temperature resistant, corrosion resistant, and wear resistant alloys. Among them, Re25-W was once a space nuclear reactor material, and later developed into a better performance Re30-W —Mo30 alloy; Re-Mo and Re-Pt are used as structural materials for atomic energy reactors, which can resist corrosion of hot bodies at 1000 ℃ and can also be used for nuclear radiation shielding.

Solutions for vacuum coating consumables in the optoelectronic industry

There are three forms of vacuum coating: evaporation coating, sputtering coating, and ion plating. It is currently the mainstream technology to achieve film growth by means of physical vapor deposition (PVD). UMM produces and supplies various forms of high-quality and high-purity metal evaporation materials and sputtering targets to ensure that users get the best coating quality.

Semiconductor equipment MOCVD thermal field solution

Metal Organic Chemical Vapor Deposition (MOCVD) is a chip epitaxial technology for preparing mixed semiconductor devices, metal and metal oxide and metal nitride film materials. The heating system is an important part of the MOCVD equipment. Whether it can heat the substrate quickly and uniformly directly affects the quality of film deposition, thickness consistency, and chip performance. The rhenium alloy under UMM has 10 years of professional production technology experience in the production of rhenium heaters for MOCVD and a complete quality control management system. It is a substitute for imported big-name or original parts of rhenium heaters for MOCVD and can carry out OEM full-process foundry. It is the number one domestic manufacturer with the most technical development strength and quality assurance ability.

Semiconductor, microelectronics industry chip heat dissipation (thermal management) materials, nuclear energy, medical equipment and many other applications, electrical and heat conduction solutions

At present and in the future, the miniaturization and multi-functionalization of electronic components put forward higher requirements for the heat dissipation of the devices. High-performance heat dissipation (thermal management) materials need to have the characteristics of low density, high thermal conductivity, and thermal expansion matching with semiconductor chip materials, good hardness, and excellent air tightness. Tungsten-copper and molybdenum-copper are often preferred as heat sink materials due to the above advantages. UMM customizes a series of high-quality tungsten copper, molybdenum copper products for users.

Ion implantation solution

Ion implantation technology refers to doping boron, phosphorus and arsenic plasma on the surface of semiconductor wafers to change its electrical characteristics and device conductivity, or to use non-doped elements such as germanium and carbon to achieve the goal of modifying the surface properties of wafer materials. The ion source is the core component of the ion implanter, mainly composed of various tungsten and molybdenum components. The ion implantation industry has very stringent requirements for impurity elements. Any excess of impurity elements may cause contamination and failure of ion implantation materials. Therefore, tungsten or molybdenum materials for ion implantation must first meet their strict requirements for chemical purity .

Chemistry and Chemical Solutions

1、Catalyst intermediate

2、Intermediates of inorganic compounds

3、Composite material intermediate

Powder consumable solutions for metal 3D printing, plasma spraying, laser cladding, and metal MIM

characteristics of small particle size, narrow particle size distribution, high sphericity, good fluidity and high bulk density. Aiming at different materials and application conditions in additive manufacturing, UMM mainly uses international mainstream advanced technologies such as plasma suspension spheroidization, plasma rotary electrode atomization, gas atomization, etc., based on quality assurance, through technical ideas and equipment details Continuous improvement and innovation to minimize the production cost of powder consumables, and accurately customize all kinds of cost-effective elementary metals, alloys, and ceramic spherical powders for users.

Tooling solutions for harsh working conditions such as high hardness, super hardness, wear resistance, impact resistance, ablation resistance, high torque, high transmission, etc

The industry generally refers to materials with a Vickers hardness HV of 10~40GPa as high-hard materials, generally represented by metal-based or ceramic-based composite materials, such as cemented carbide, silicon carbide, corundum (alumina), etc.; Vickers hardness HV Those larger than 40GPa are called superhard materials, which mainly refer to diamond and cubic boron nitride. Challenging and severe working conditions require materials to meet the conditions of high hardness and wear resistance, as well as harsh requirements such as ultra-high temperature, high strength, impact resistance, high transmission, and large torque. UMM precision manufactures the following three types of materials, which are used in the preparation of special tools, pumps, valves, shafts, etc., against harsh working conditions such as heavy machinery, petrochemical, aerospace, nuclear power equipment, rail transit, ship power, and special equipment. In terms of key structural components such as transmission parts and wear parts, it has unparalleled performance advantages.

High temperature thermal container (high temperature crucible) solutions

Refractory metal tungsten, rhenium, molybdenum and their alloy materials are often used to make high-temperature heat vessels (high-temperature crucibles) above 2000°C. They have high melting point, high strength and hardness, good high-temperature performance, low resistivity, small expansion coefficient, and electronic escape. Feature such as small effort. As a container for high-temperature environments, this type of crucible is widely used in the field of sapphire crystal growth, rare earth smelting, coating and other industries.

Plasma electrodes, special welding electrodes, ultra-high temperature electro-thermoelectric vacuum solutions

Electrodes for plasma spraying, argon arc welding, and pulse arc welding are usually made of tungsten-doped thorium or rare earth cerium. Tungsten-thorium and tungsten-cerium electrodes not only have a limited service life, but also thorium is a radioactive element. Tungsten-doped thorium is in the manufacturing and use process It is harmful to the human body and the environment. The use of tungsten rhenium electrode can effectively inhibit the growth of crystal grains caused by recrystallization during use of the electrode, improve the electron emission characteristics of the material, reduce the formation of hole defects and burnout of the electrode under the action of arc, and extend the service life of the electrode 2~ 3 times, and environmental protection without any radioactive hazards. UMM uses new tungsten rhenium electrodes to replace tungsten thorium and tungsten cerium electrodes, which greatly improves economy and efficiency.

High temperature thermocouple solutions

High-quality tungsten rhenium thermocouple wire (W-3Re)/(W-25Re), (W-5Re)/(W-26Re) has accurate, stable and uniform temperature-thermoelectric potential performance, which can be used to manufacture 1000- 2300℃ high temperature measurement tungsten rhenium thermocouple. The company can customize tungsten rhenium thermocouple wires of different specifications and brands according to customer needs, and also provide different types of armored tungsten rhenium thermocouples.

Friction stir welding solutions

The joints obtained by welding magnesium, aluminum, copper, titanium alloys or heavy steel by traditional fusion welding methods have defects such as pores and microcracks, and the heat-affected zone is wide and the deformation is large, which limits the welding structure and restricts the weldment in related fields. Wide range of applications. Friction stir welding (Friction stir welding, FSW) as a new type of solid phase welding technology can effectively solve this problem. Friction stir welding does not require filler metal, the welding heat affected zone is small, the joint deformation is small, and the welding process is free of smoke and dust pollution. It is a green and environmentally friendly welding technology.

Special welding wire solder solutions

The special alloy welding wire designed and produced by the additive effect of some refractory metal elements has excellent high temperature strength and creep resistance, can enhance the high temperature wear resistance of the material, and greatly reduce the damage caused by cold and heat fatigue. The material after welding with this special alloy wire has room temperature hardness of 61HRC, good plasticity, and low welding crack tendency. It is suitable for remanufacturing and repairing parts used under high temperature conditions, such as hot rolls.

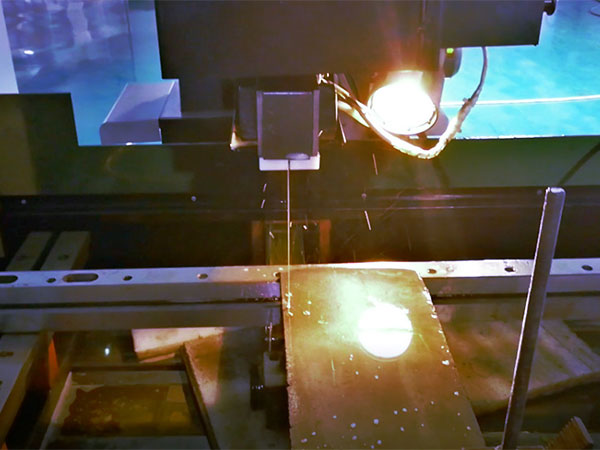

High-efficiency and long-life wire cutting solutions

UMM provides high-efficiency and long-life molybdenum wire for wire-cutting industry. This molybdenum wire product adopts a special composition formula and is drawn by a special process. It is more electrochemically resistant than ordinary wire-cut molybdenum wire. The advantages of ablation and longer service life.

Medical equipment,medical equipment field solutions

1、Exclusive production and supply of tungsten and rhenium needle accessories for medical LEEP knife instead of imported.

2、Rotating anode target for CT machine tube. The supply and maintenance of high-power medical CT equipment in my country has long been monopolized by GE, Philips, and Siemens. Not only does the equipment purchase cost a lot, but the key consumable CT tube is expensive, so the localization of CT machine and tube The strategy is of great significance. The tungsten rhenium alloy manufactured by our company is the key material for the anode target, which is the key part of the tube component. Outai Rare Materials has rich experience in manufacturing refractory alloy powder metallurgy products, and can produce high-quality rotating anode targets for CT tube according to customer's technical requirements.

Artificial bone joints, biological implant solutions

1. Casting cobalt-chromium-molybdenum alloy;

2. Titanium alloy;

3. Molybdenum rhenium alloy;

News comes from the frontiers of international medical materials: As a new orthopedic implant material, molybdenum rhenium alloy is considered to be the most developed due to its good biocompatibility, high strength, and excellent imaging performance under imaging diagnosis. Potential new generation of biomedical materials. Outai Thin Materials has carried out research and development cooperation of orthopedic implant materials for nearly eight years with large-scale medical device manufacturers in Europe and the United States. At present, it can produce excellent delivery performance and various specifications of orthopedic implant special molybdenum-rhenium alloy intermediate materials, such as bars and plates. , Tubes and foils, and complete sets of human bone implants jointly developed by partners. At present, the molybdenum-rhenium implant jointly developed by our company and foreign partners has successfully passed the US FDA certification, and is looking for application promotion partners in the Chinese medical market.

Counterweight solutions

High-density tungsten alloys are widely used in the national economy and national defense industry. Aerospace and aerospace industries are used for gyroscope rotors, counterweights and balance materials, as well as guides and shock absorbers; petroleum, nuclear, and medical equipment industries are used as shielding materials to prevent various rays; machinery industries are used as die-casting Moulds, knife holders, boring bars and automatic watch hammers; used in the weapon industry as armor piercing materials and medicine cover materials; used in the electrical industry as 284' riveting heads and switch contact materials; sports goods can also be used as golf racking Heavy materials. UMM integrates research, development, production, sales and service of high-density tungsten alloy products, and produces various complex shapes, high precision, high difficulty, and high performance fine structure parts.

Rare metal cultural and creative art collection, precious metal investment preservation solutions

It can be customized or manufactured in batches according to the customer's design drawings. Our price is real. We have strict inspections on the quality of materials, such as purity testing, precise control of ingredients, and stable market outlook.