Products Center

Top ten high-end specialty thin material products

Products

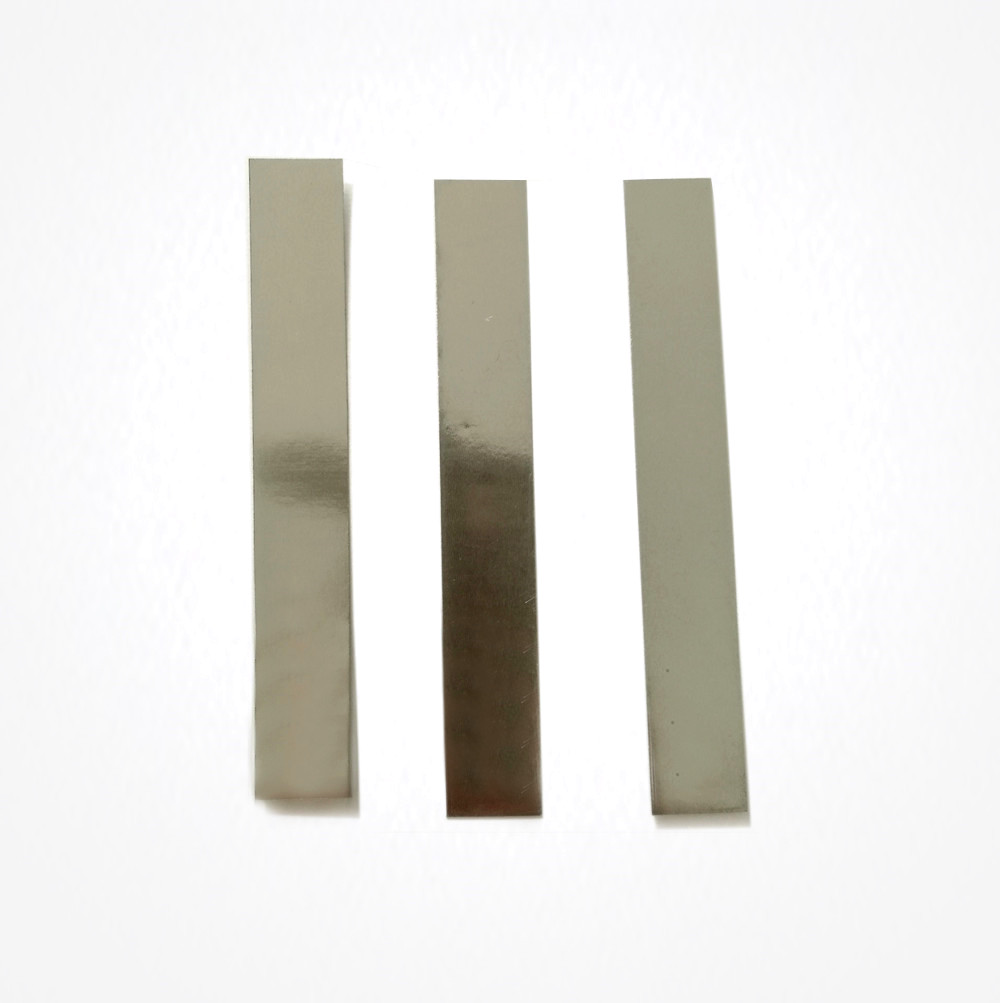

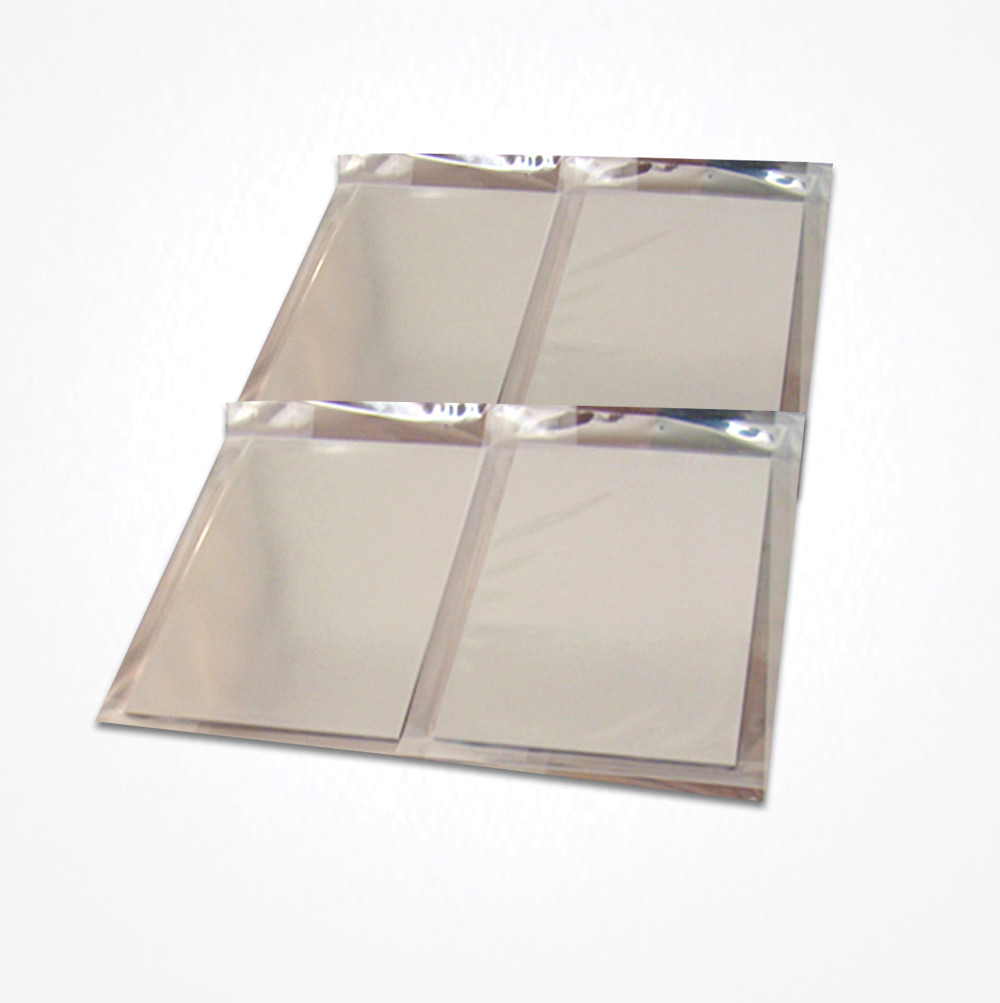

Rhenium Sheet:T(0.1-1)*W(0.5-500)mm, Can be customized as per requirement

Rhenium Foil|Ribbon:T(0.04-0.21)*W(0.5-80)mm, Can be customized as per requirement

Appearance: Silver metallic plate | sheet | Foil

Application: Rhenium plate | sheet | Foil is mainly used as electrode materials in high temperature and harsh conditions, for production of electronic components and ultra high temperature heater tube with metal evaporation in semiconductor and electronics industry. The high temperature heating parts need to work under special conditions, compared with other materials, pure rhenium heating has better electrical performance, longer life expectancy, these significant properties are more resistant to harsh working atmosphere and favored by the users. Rhenium foil is mainly used for chemical vapor phase deposition coating and film(CVD) and physical vapor deposition(PVD) procss, including hot electron beam evaporation, low temperature organic evaporation, atomic layer deposition(ALD) and metal organic chemical vapor deposition product(MOCVD) etc. Others can be used for manufacturing special parts in aerospace equipment

Specification: chemical purity Re 99.99%min(calculated by subtractive method, except gas element), density 21g/cc min.

Size:

Rhenium Plate:T(1-20)*W(0.5-500)mm, Can be customized as per requirement

Rhenium Sheet:T(0.1-1)*W(0.5-500)mm, Can be customized as per requirement

Rhenium Foil|Ribbon:T(0.04-0.21)*W(0.5-80)mm, Can be customized as per requirement

Typical chemical analysis

|

Main content: Re≥99.99% (gas elements not included) |

|||||||

|

Impurity elements (≯, %) |

|||||||

|

Na |

0.0005 |

Ti |

0.0001 |

Cu |

0.0001 |

Sb |

0.0001 |

|

Mg |

0.0001 |

V |

0.0001 |

Zn |

0.0001 |

Ta |

0.0001 |

|

Al |

0.0005 |

Cr |

0.0005 |

As |

0.0001 |

W |

0.0010 |

|

Si |

0.0005 |

Mn |

0.0001 |

Zr |

0.0001 |

Pb |

0.0001 |

|

P |

0.0005 |

Fe |

0.0010 |

Mo |

0.0010 |

Bi |

0.0001 |

|

K |

0.0005 |

Co |

0.0001 |

Cd |

0.0001 |

Se |

0.0001 |

|

Ca |

0.0005 |

Ni |

0.0005 |

Sn |

0.0001 |

Tl |

0.0001 |

|

C |

0.0020 |

N |

0.0010 |

O |

0.0100 |

H |

0.0020 |

|

主含量:Re≥99.99%(气体元素不计入内) |

|||||||

|

杂质成分(≯,%) |

|||||||

|

Na |

0.0005 |

Ti |

0.0001 |

Cu |

0.0001 |

Sb |

0.0001 |

|

Mg |

0.0001 |

V |

0.0001 |

Zn |

0.0001 |

Ta |

0.0001 |

|

Al |

0.0005 |

Cr |

0.0005 |

As |

0.0001 |

W |

0.0010 |

|

Si |

0.0005 |

Mn |

0.0001 |

Zr |

0.0001 |

Pb |

0.0001 |

|

P |

0.0005 |

Fe |

0.0010 |

Mo |

0.0010 |

Bi |

0.0001 |

|

K |

0.0005 |

Co |

0.0001 |

Cd |

0.0001 |

Se |

0.0001 |

|

Ca |

0.0005 |

Ni |

0.0005 |

Sn |

0.0001 |

Tl |

0.0001 |

|

C |

0.0020 |

N |

0.0010 |

O |

0.0100 |

H |

0.0020 |

Everyone is watching

Products

Precious metal functional materials

High-quality optoelectronic materials/high-purity targets

Refractory metals and their alloys

Special alloy/special steel

Spherical | Nano powder

Biomedical/3D printing products

Compound

Rare metals and their alloys

Rare metals and their alloysRare Metal Concept Cultural/Art/Collectible

Nuclear energy Nuclear power Nuclear industry

High temperature heat container

Microelectronics industry Chip thermal sink

Semiconductor equipment MOCVD thermal field

High efficiency & long life Wire for wire cutting

Medical equipment Medical instruments

Artificial bone joint Bioimplantation

Rare metal cultural & creative art collection Precious metal

Plasma|Special Welding Electrode

Ultra Minor Metals Ltd (UMM) all rights reserved 湘ICP备17001881号 by:www.300.cnchangsha