Products Center

Top ten high-end specialty thin material products

Products

Product manual

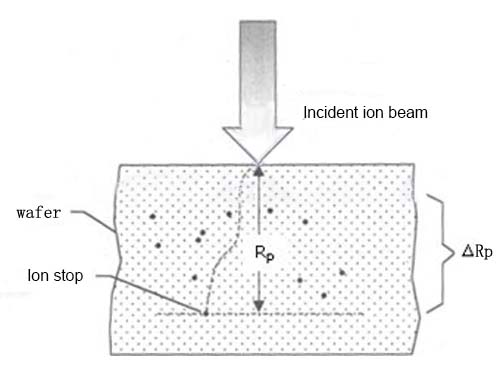

Ion implantation is a kind of material surface modification high and new technology that has been vigorously developed and widely used internationally in the past 30 years. It has realized the optimization of the surface performance of the material or can obtain some new excellent performance. Due to the unique and prominent features of this high-tech, it is a very important technology in modern integrated circuit manufacturing. It uses an ion implanter to achieve semiconductor doping and change the conductivity of the semiconductor and the structure of the transistor.

Application

Since the ion source is converted to plasma ions during ion implantation, the operating temperature will be above 2000 ℃, and the ion beam will also generate a large amount of kinetic energy when the ion beam erupts, and the general metal will quickly melt. Therefore, inert metals with relatively large mass and density are required to maintain the direction of the ion beam and increase component durability. Tungsten material has the advantages of stable high temperature chemical performance, low thermal denaturation and long service life. It has become the first choice for ion source parts and consumables of ion implanters in the semiconductor industry. These are collectively referred to as ion implanted tungsten parts

Everyone is watching

Products

Precious metal functional materials

High-quality optoelectronic materials/high-purity targets

Refractory metals and their alloys

Special alloy/special steel

Spherical | Nano powder

Biomedical/3D printing products

Compound

Rare metals and their alloys

Rare metals and their alloysRare Metal Concept Cultural/Art/Collectible

Nuclear energy Nuclear power Nuclear industry

High temperature heat container

Microelectronics industry Chip thermal sink

Semiconductor equipment MOCVD thermal field

High efficiency & long life Wire for wire cutting

Medical equipment Medical instruments

Artificial bone joint Bioimplantation

Rare metal cultural & creative art collection Precious metal

Plasma|Special Welding Electrode

Ultra Minor Metals Ltd (UMM) all rights reserved 湘ICP备17001881号 by:www.300.cnchangsha