Industry News

Learn more about us through the industry

News

Reasons for 3D printing of spherical tungsten powder

- Categories:Spherical powder news

- Author:

- Origin:

- Time of issue:2022-04-30 15:09

- Views:0

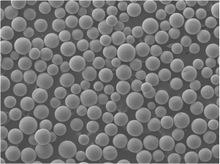

(Summary description)As an important raw material for tungsten production, the physical and chemical properties of spherical tungsten powder (W) directly affect the quality and use of tungsten products.

Reasons for 3D printing of spherical tungsten powder

(Summary description)As an important raw material for tungsten production, the physical and chemical properties of spherical tungsten powder (W) directly affect the quality and use of tungsten products.

- Categories:Spherical powder news

- Author:

- Origin:

- Time of issue:2022-04-30 15:09

- Views:0

As an important raw material for tungsten production, the physical and chemical properties of spherical tungsten powder (W) directly affect the quality and use of tungsten products. Normally, the higher the purity of the powder and the lower the oxygen and carbon content, the better the thermodynamic properties of the tungsten machining material. However, the physical and chemical properties of the powder are not the only factor that determines the quality of tungsten products. The performance of tungsten parts is also restricted by the production process. Compared to traditional powder metallurgy methods, 3D printing technology is more suitable for manufacturing tungsten parts for the following reasons:

Powder metallurgy is a process technology that uses metal powder as a raw material, after forming and sintering, to manufacture products of various shapes. The advantages are: 1) Special materials can be processed; 2) High material utilization rate; 3) Mass production is possible; 4) High accuracy of material distribution. The disadvantages are: 1) The product has poor strength and toughness; 2) It cannot be made into large-scale products; 3) Only some parts with simple structures can be prepared; 4) The cost of compression molding is high.

Scan the QR code to read on your phone

Top dynamic rankings

2024-03-04

Scan the QR code and follow the official account

Products

Precious metal functional materials

High-quality optoelectronic materials/high-purity targets

Refractory metals and their alloys

Special alloy/special steel

Spherical | Nano powder

Biomedical/3D printing products

Compound

Rare metals and their alloys

Rare metals and their alloysRare Metal Concept Cultural/Art/Collectible

Nuclear energy Nuclear power Nuclear industry

High temperature heat container

Microelectronics industry Chip thermal sink

Semiconductor equipment MOCVD thermal field

High efficiency & long life Wire for wire cutting

Medical equipment Medical instruments

Artificial bone joint Bioimplantation

Rare metal cultural & creative art collection Precious metal

Plasma|Special Welding Electrode

Ultra Minor Metals Ltd (UMM) all rights reserved 湘ICP备17001881号 by:www.300.cnchangsha