Industry News

Learn more about us through the industry

News

What is spherical tungsten carbide powder

- Categories:Spherical powder news

- Author:

- Origin:

- Time of issue:2022-04-27 13:19

- Views:0

(Summary description)As one of the main production raw materials of cemented carbide, the physical and chemical properties of tungsten carbide (WC) powder, such as particle shape, particle size, particle size distribution, oxygen content

What is spherical tungsten carbide powder

(Summary description)As one of the main production raw materials of cemented carbide, the physical and chemical properties of tungsten carbide (WC) powder, such as particle shape, particle size, particle size distribution, oxygen content

- Categories:Spherical powder news

- Author:

- Origin:

- Time of issue:2022-04-27 13:19

- Views:0

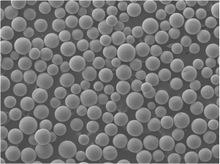

As one of the main production raw materials of cemented carbide, the physical and chemical properties of tungsten carbide (WC) powder, such as particle shape, particle size, particle size distribution, oxygen content, carbon content, bulk density, etc., will directly affect the quality of alloy products. Today, with the gradual optimization of the production process of cemented carbide, the market demand for spherical tungsten carbide powder is also increasing.

1. The concept of spherical WC powder

It is mainly composed of refractory metal tungsten and non-metallic carbon, and contains a small amount of impurity elements such as Co, Cr, Ti, Ta, Nb, V, Mn, Ni, Mo, O, etc.

2. Properties of spherical WC powder

The appearance is black powder, the melting point is 2870℃, the boiling point is 6000℃, the density is 15.63g/cm3, the bulk density is greater than 7.0g/cm3, the tap density is greater than 7.5g/cm3, and the flow performance is less than 10.0s/50g. It has the characteristics of high hardness, low thermal expansion coefficient, high compressive strength, large elastic modulus and smooth surface. However, due to its high hardness, its processing performance is poor, so it is more suitable for 3D printing.

3. Production process of spherical WC powder

1) Melting method: The raw material powder (tungsten powder and carbon black or tungsten powder, carbon black and tungsten carbide) is melted into a liquid state, and the droplets will be in the centrifugal rotation method, rotary atomization method or gas atomization method. Spherical tungsten carbide is formed on the surface.

2) Modified irregular tungsten carbide: The irregular WC is melted into a liquid state, and then the spherical tungsten carbide powder is made by the plasma spheroidization method or the resistance heat spheroidization method.

Scan the QR code to read on your phone

Top dynamic rankings

Scan the QR code and follow the official account

Products

Precious metal functional materials

High-quality optoelectronic materials/high-purity targets

Refractory metals and their alloys

Special alloy/special steel

Spherical | Nano powder

Biomedical/3D printing products

Compound

Rare metals and their alloys

Rare metals and their alloysRare Metal Concept Cultural/Art/Collectible

Nuclear energy Nuclear power Nuclear industry

High temperature heat container

Microelectronics industry Chip thermal sink

Semiconductor equipment MOCVD thermal field

High efficiency & long life Wire for wire cutting

Medical equipment Medical instruments

Artificial bone joint Bioimplantation

Rare metal cultural & creative art collection Precious metal

Plasma|Special Welding Electrode

Ultra Minor Metals Ltd (UMM) all rights reserved 湘ICP备17001881号 by:www.300.cnchangsha