Industry News

Learn more about us through the industry

News

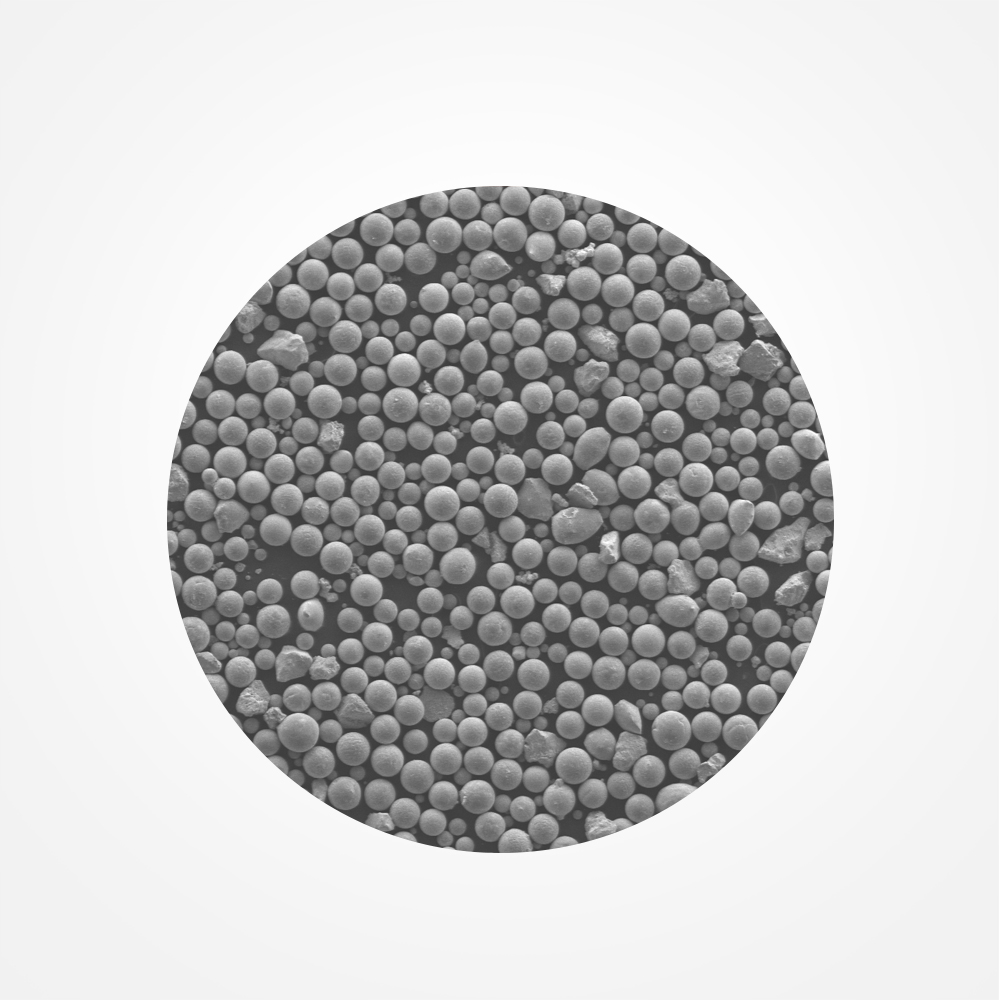

Uses and application fields of quality Spherical vanadium powder

- Categories:Spherical powder news

- Author:

- Origin:

- Time of issue:2022-01-11 14:30

- Views:0

(Summary description)The quality Spherical vanadium powder is a high melting point refractory rare metal, its main product forms are: vanadium pentoxide, vanadium trioxide, ferrovanadium, vanadium nitride, etc.

Uses and application fields of quality Spherical vanadium powder

(Summary description)The quality Spherical vanadium powder is a high melting point refractory rare metal, its main product forms are: vanadium pentoxide, vanadium trioxide, ferrovanadium, vanadium nitride, etc.

- Categories:Spherical powder news

- Author:

- Origin:

- Time of issue:2022-01-11 14:30

- Views:0

The quality Spherical vanadium powder is a high melting point refractory rare metal, its main product forms are: vanadium pentoxide, vanadium trioxide, ferrovanadium, vanadium nitride, etc. Among them, vanadium pentoxide and vanadium trioxide are the most important vanadium oxides in actual production, and they are the main raw materials for the preparation of subsequent vanadium products such as ferrovanadium, vanadium nitride and vanadium carbide.

The products of quality Spherical vanadium powder are divided into primary products, secondary products and tertiary products. Primary products include vanadium-bearing minerals, concentrates, vanadium slag, spent petroleum refining spent catalysts, spent catalysts and other residues. Secondary products include vanadium pentoxide and can also be a useful industrial product, namely a catalyst for the production of sulfuric acid and a catalyst for petroleum refining. The tertiary products include ferrovanadium, vanadium-aluminum alloy, molybdenum-vanadium-aluminum alloy, silicon-manganese-vanadium ferroalloy and vanadium compounds, of which ferrovanadium is the most important vanadium material, accounting for 85% of vanadium consumption.

The quality Spherical vanadium powder is an important alloying element mainly used in the steel industry. Vanadium-containing steel has excellent properties such as high strength, high toughness and good wear resistance, so it is widely used in machinery, automobile, shipbuilding, railway, aviation, bridge, electronic technology, national defense industry and other industries. 85%, the steel industry accounts for the largest proportion of vanadium use. The demand in the steel industry directly affects the vanadium market. About 10% of the quality Spherical vanadium powder is used to produce titanium alloys for the aerospace industry. Vanadium can be used as a stabilizer and strengthening agent in titanium alloys, which makes titanium alloys have good ductility and plasticity. In addition, vanadium is mainly used in the chemical industry as a catalyst and a colorant. Vanadium is also used to produce rechargeable hydrogen batteries or vanadium redox batteries.

Scan the QR code to read on your phone

Top dynamic rankings

Scan the QR code and follow the official account

Products

Precious metal functional materials

High-quality optoelectronic materials/high-purity targets

Refractory metals and their alloys

Special alloy/special steel

Spherical | Nano powder

Biomedical/3D printing products

Compound

Rare metals and their alloys

Rare metals and their alloysRare Metal Concept Cultural/Art/Collectible

Nuclear energy Nuclear power Nuclear industry

High temperature heat container

Microelectronics industry Chip thermal sink

Semiconductor equipment MOCVD thermal field

High efficiency & long life Wire for wire cutting

Medical equipment Medical instruments

Artificial bone joint Bioimplantation

Rare metal cultural & creative art collection Precious metal

Plasma|Special Welding Electrode

Ultra Minor Metals Ltd (UMM) all rights reserved 湘ICP备17001881号 by:www.300.cnchangsha