Industry News

Learn more about us through the industry

News

Details about iridium particles products

- Categories:Iridium target news

- Author:

- Origin:

- Time of issue:2021-12-23 16:35

- Views:0

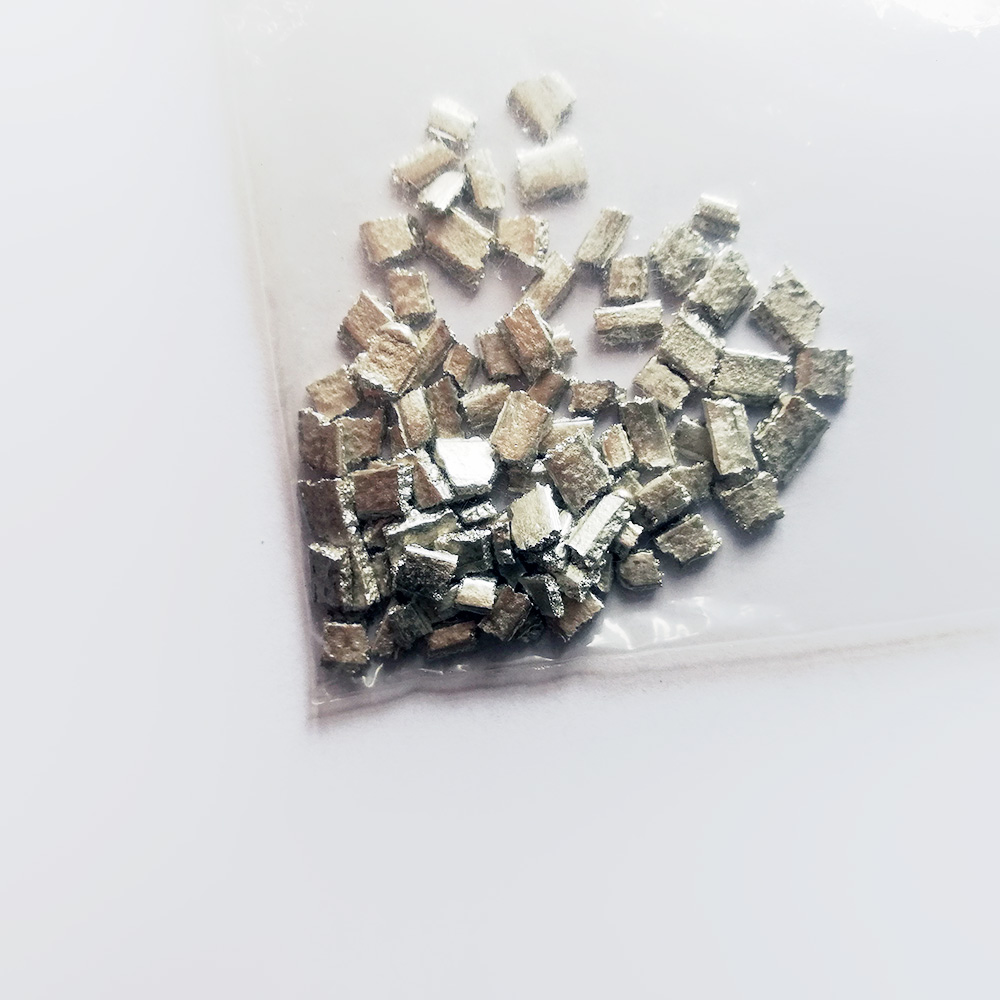

(Summary description)Iridium particles are a hard silver metal. It is almost as non-reactive as gold. It has a high density and melting point. Iridium is the second most dense metal (post-osmium), and it is also the most corrosion-resistant metal.

Details about iridium particles products

(Summary description)Iridium particles are a hard silver metal. It is almost as non-reactive as gold. It has a high density and melting point. Iridium is the second most dense metal (post-osmium), and it is also the most corrosion-resistant metal.

- Categories:Iridium target news

- Author:

- Origin:

- Time of issue:2021-12-23 16:35

- Views:0

Iridium particles are a hard silver metal. It is almost as non-reactive as gold. It has a high density and melting point. Iridium is the second most dense metal (post-osmium), and it is also the most corrosion-resistant metal. Although only certain molten salts and halogens corrode solid iridium, finely divided iridium dust is more reactive and flammable.

Iridium particles are the most corrosion-resistant materials known. It is used in special alloys and forms an alloy with with, which can be used for pen nibs and compass bearings. It is used to make standard instrument bars, which is an alloy of 90% platinum and 10% iridium. Due to its high melting point and low reactivity, it is also used for spark plug contacts. Pure iridium is extremely fragile, and it is difficult to weld because the areas affected by heat will crack, but by adding a small amount of titanium and zirconium (each content is about 0.2%), you can make it more ductile.

Biological heat and corrosion resistance make iridium particles an important alloying agent. Certain long-life aircraft engine parts are made of iridium alloys, and iridium-titanium alloys are used in deep-water pipelines due to their corrosion resistance. Iridium is also used as a hardener in platinum alloys. The Vickers hardness of pure platinum is 56HV, while platinum containing 50% iridium can reach more than 500 HV. Devices that must withstand extremely high temperatures are usually made of iridium. For example, high-temperature crucibles made of iridium are used in the Czeklaussky process to produce oxide single crystals (such as sapphire), which are used in computer storage devices and solid-state lasers.

Iridium particles have no known biological effects and have low toxicity. Iridium is one of the rarest elements on earth. It is not found in nature, but in the sediments deposited by rivers. It is recovered commercially as a by-product of nickel refining. There is a very thin layer of iridium in the earth's crust. It is believed that this is caused by a large meteor or asteroid hitting the earth. The iridium content of meteors and asteroids is higher than that of the earth's crust. The impact will cause a huge dust cloud, depositing iridium all over the world. Some scientists believe that this may be the same as the meteor or asteroid impact that wiped out the dinosaurs. Iridium was discovered with Smithson Tennant in London in 1803. When crude platinum is dissolved in dilute nitric acid, dilute nitric acid is a mixture of nitric acid and hydrochloric acid, it leaves a black residue, which is considered graphite. Tennant didn't think so, and by alternating treatment with alkali and acid, he was able to divide it into two new elements. The substances he announced at the Royal Institute of London were named one type of iridium because its salt is so rich, and the other because of its strange smell (see). Although it may seem difficult to handle, a group of chemists, including chemist Humphrey David, proved in 1813 that iridium does melt like other metals. To this end, they exposed it to the powerful current generated by a large number of batteries.

Scan the QR code to read on your phone

Top dynamic rankings

Scan the QR code and follow the official account

Products

Precious metal functional materials

High-quality optoelectronic materials/high-purity targets

Refractory metals and their alloys

Special alloy/special steel

Spherical | Nano powder

Biomedical/3D printing products

Compound

Rare metals and their alloys

Rare metals and their alloysRare Metal Concept Cultural/Art/Collectible

Nuclear energy Nuclear power Nuclear industry

High temperature heat container

Microelectronics industry Chip thermal sink

Semiconductor equipment MOCVD thermal field

High efficiency & long life Wire for wire cutting

Medical equipment Medical instruments

Artificial bone joint Bioimplantation

Rare metal cultural & creative art collection Precious metal

Plasma|Special Welding Electrode

Ultra Minor Metals Ltd (UMM) all rights reserved 湘ICP备17001881号 by:www.300.cnchangsha