Industry News

Learn more about us through the industry

News

Spherical tungsten powder preparation technology

- Categories:Spherical powder news

- Author:

- Origin:

- Time of issue:2021-12-21 13:27

- Views:0

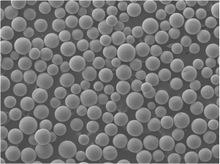

(Summary description)Spherical tungsten powder is more and more widely used in many fields because of its good fluidity and high tap density. In the field of thermal spraying, because of its good fluidity, Spherical tungsten powder makes the coating more uniform and dense, so the coating has better wear resistance

Spherical tungsten powder preparation technology

(Summary description)Spherical tungsten powder is more and more widely used in many fields because of its good fluidity and high tap density. In the field of thermal spraying, because of its good fluidity, Spherical tungsten powder makes the coating more uniform and dense, so the coating has better wear resistance

- Categories:Spherical powder news

- Author:

- Origin:

- Time of issue:2021-12-21 13:27

- Views:0

Spherical tungsten powder is more and more widely used in many fields because of its good fluidity and high tap density. In the field of thermal spraying, because of its good fluidity, Spherical tungsten powder makes the coating more uniform and dense, so the coating has better wear resistance; in the field of powder metallurgy, forming parts made of spherical powder are used High density, uniform shrinkage of the molded parts during the sintering process, so the obtained products have high precision and good performance, and have obvious advantages in the application of advanced powder metallurgy forming technology such as injection molding, gel injection molding and additive manufacturing.

1. Aerosolization method

The gas atomization method (GA) mainly uses an atomizing nozzle to generate high-speed, high-pressure gas to pulverize the molten metal stream, turning it into fine droplets, and rapidly cooling and solidifying into spherical particles. According to incomplete statistics, metal powders for additive manufacturing in the world today account for 50% to 60% of the total output. After continuous innovation and improvement, the GA method has become the main source of high-performance Spherical tungsten powder for additive manufacturing. One of the production methods. The particle size of the powder prepared by GA method usually has a wide distribution range and needs to consume a large amount of specific gas; when the powder size distribution range is wide, it is usually necessary to separate the larger or smaller particle size powder, which will greatly reduce the production efficiency; in addition, GA The widespread existence of hollow powder and satellite particles in the law still cannot be completely resolved.

2. Plasma torch atomization method

The plasma torch atomization method is to feed metals and their alloys into the furnace at a constant feeding speed in the form of bar stock, wire, particles or liquid steam through a special feeding device, and use a plasma torch arranged on the furnace body The generated focused plasma jet melts and atomizes the material, and then cools to obtain a spherical powder. The system is protected by an inert atmosphere during the whole process, which can reduce powder oxidation and obtain high-purity powder.

This technology uses plasma as the atomization heat source, which can make the target material melt more fully, combined with the reasonable control of the cooling rate, can obtain powder with high sphericity, low oxygen content and fine particle size. However, because this technology uses a high-power plasma gun as a heat source, it consumes a lot of energy, which will increase the cost of preparing Spherical tungsten powder. In addition, the spherical powder obtained by the plasma torch atomization method has a wide particle size distribution, and particle size classification must be carried out before use, and the yield of fine powder is low, and the product cost is high, which limits the promotion and application of large areas.

3. Rotating electric atomization method

The rotating electrode atomization method (PREP) is to make the base metal alloy into the electrode rod and then load it into the transmission device, make it rotate at a high speed in an inert protective atmosphere, and at the same time it is heated and melted by the plasma arc, and the formed liquid film is subjected to centrifugal force A technology that disperses and flies away from the electrode rod section, and finally solidifies rapidly under the action of surface tension to form Spherical tungsten powder. The method regulates the particle size of the powder by changing the diameter of the electrode rod, the rotation speed and the size of the plasma arc current, and is suitable for the preparation of powders such as titanium alloys and high-temperature alloys for additive manufacturing of aerospace parts. The obtained powder has good sphericity, narrow particle size distribution, clean surface, few inclusions, no hollow powder, and good fluidity. The disadvantage is that the powder is not easy to prepare, the material utilization rate is not high, and the traditional PREP method is due to the diameter of the electrode rod. Small (≤50mm), low speed (limit speed is 15000r/min), the prepared powder is relatively coarse, not suitable for SLM additive manufacturing. Increasing the diameter of the electrode rod and the limiting speed, and overcoming the high-speed dynamic sealing technology are the key to the PREP method to obtain finer powder.

Scan the QR code to read on your phone

Top dynamic rankings

2024-03-04

Scan the QR code and follow the official account

Products

Precious metal functional materials

High-quality optoelectronic materials/high-purity targets

Refractory metals and their alloys

Special alloy/special steel

Spherical | Nano powder

Biomedical/3D printing products

Compound

Rare metals and their alloys

Rare metals and their alloysRare Metal Concept Cultural/Art/Collectible

Nuclear energy Nuclear power Nuclear industry

High temperature heat container

Microelectronics industry Chip thermal sink

Semiconductor equipment MOCVD thermal field

High efficiency & long life Wire for wire cutting

Medical equipment Medical instruments

Artificial bone joint Bioimplantation

Rare metal cultural & creative art collection Precious metal

Plasma|Special Welding Electrode

Ultra Minor Metals Ltd (UMM) all rights reserved 湘ICP备17001881号 by:www.300.cnchangsha