Industry News

Learn more about us through the industry

News

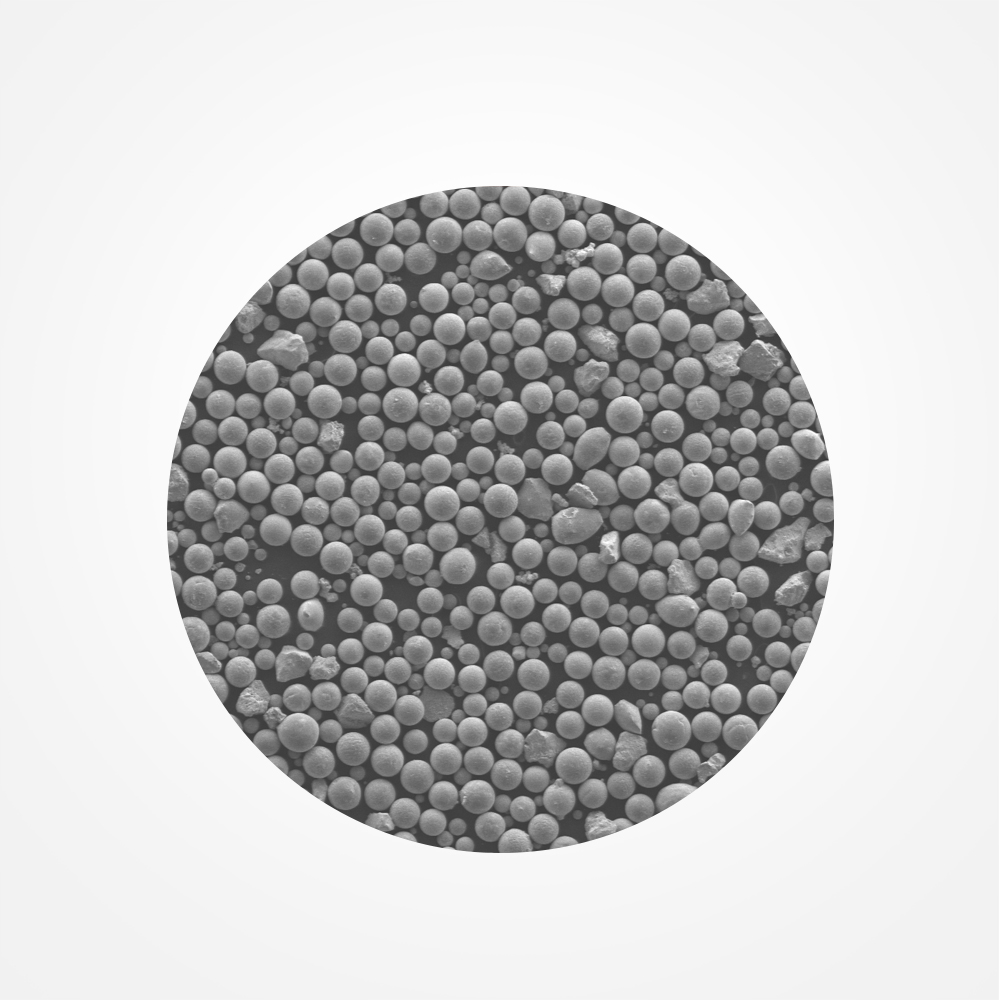

Spherical vanadium powder preparation method, application and process

- Categories:Spherical powder news

- Author:

- Origin:

- Time of issue:2021-12-16 17:34

- Views:0

(Summary description)At present, the main production methods of Spherical vanadium powder are: reduction method, molten salt electrolysis method, mechanical alloying method, crushing method and inert gas atomization method.

Spherical vanadium powder preparation method, application and process

(Summary description)At present, the main production methods of Spherical vanadium powder are: reduction method, molten salt electrolysis method, mechanical alloying method, crushing method and inert gas atomization method.

- Categories:Spherical powder news

- Author:

- Origin:

- Time of issue:2021-12-16 17:34

- Views:0

At present, the main production methods of Spherical vanadium powder are: reduction method, molten salt electrolysis method, mechanical alloying method, crushing method and inert gas atomization method.

1. The method for preparing Spherical vanadium powder by metal gas-based reduction, the steps include: vanadium oxide is used as a raw material, active metal is used as a reducing agent, and the active metal contacts the raw material in a gas form to undergo a thermal reduction reaction, and the reaction product is obtained by pickling, filtering, and drying Spherical vanadium powder.

2. The preparation method of Spherical vanadium powder is to first mix the vanadium-containing material with alkali metal or alkaline earth metal chloride salt, then mix with calcium hydride, and then perform vacuum thermal reduction to obtain the reduced product; then use ammonium chloride solution and alkali in turn Spherical vanadium powder can be obtained by washing liquid and acid liquid, and finally performing dehydrogenation treatment;

The preparation of conventional Spherical vanadium powder mainly adopts reduction method and molten salt electrolysis method. Due to the high oxygen content of Spherical vanadium powder prepared by the reduction method, its utilization rate shows a downward trend. The powder of molten salt spray electrolysis method is dendritic, and the post-processing environment is under high pressure. The crucible gas atomization method is a method in which after the metal is melted in the crucible, the molten metal flows through a fine nozzle and blows into the high-speed rotating gas to produce powder. Spherical vanadium powder is a high melting point metal, and it is very sensitive to the structure. It is difficult to smelt when melted in a crucible, and it is easily contaminated by refractory materials, and its purity cannot be guaranteed.

Scan the QR code to read on your phone

Top dynamic rankings

Scan the QR code and follow the official account

Products

Precious metal functional materials

High-quality optoelectronic materials/high-purity targets

Refractory metals and their alloys

Special alloy/special steel

Spherical | Nano powder

Biomedical/3D printing products

Compound

Rare metals and their alloys

Rare metals and their alloysRare Metal Concept Cultural/Art/Collectible

Nuclear energy Nuclear power Nuclear industry

High temperature heat container

Microelectronics industry Chip thermal sink

Semiconductor equipment MOCVD thermal field

High efficiency & long life Wire for wire cutting

Medical equipment Medical instruments

Artificial bone joint Bioimplantation

Rare metal cultural & creative art collection Precious metal

Plasma|Special Welding Electrode

Ultra Minor Metals Ltd (UMM) all rights reserved 湘ICP备17001881号 by:www.300.cnchangsha