Industry News

Learn more about us through the industry

News

What is Spherical vanadium powder

- Categories:Spherical powder news

- Author:

- Origin:

- Time of issue:2021-12-15 17:32

- Views:0

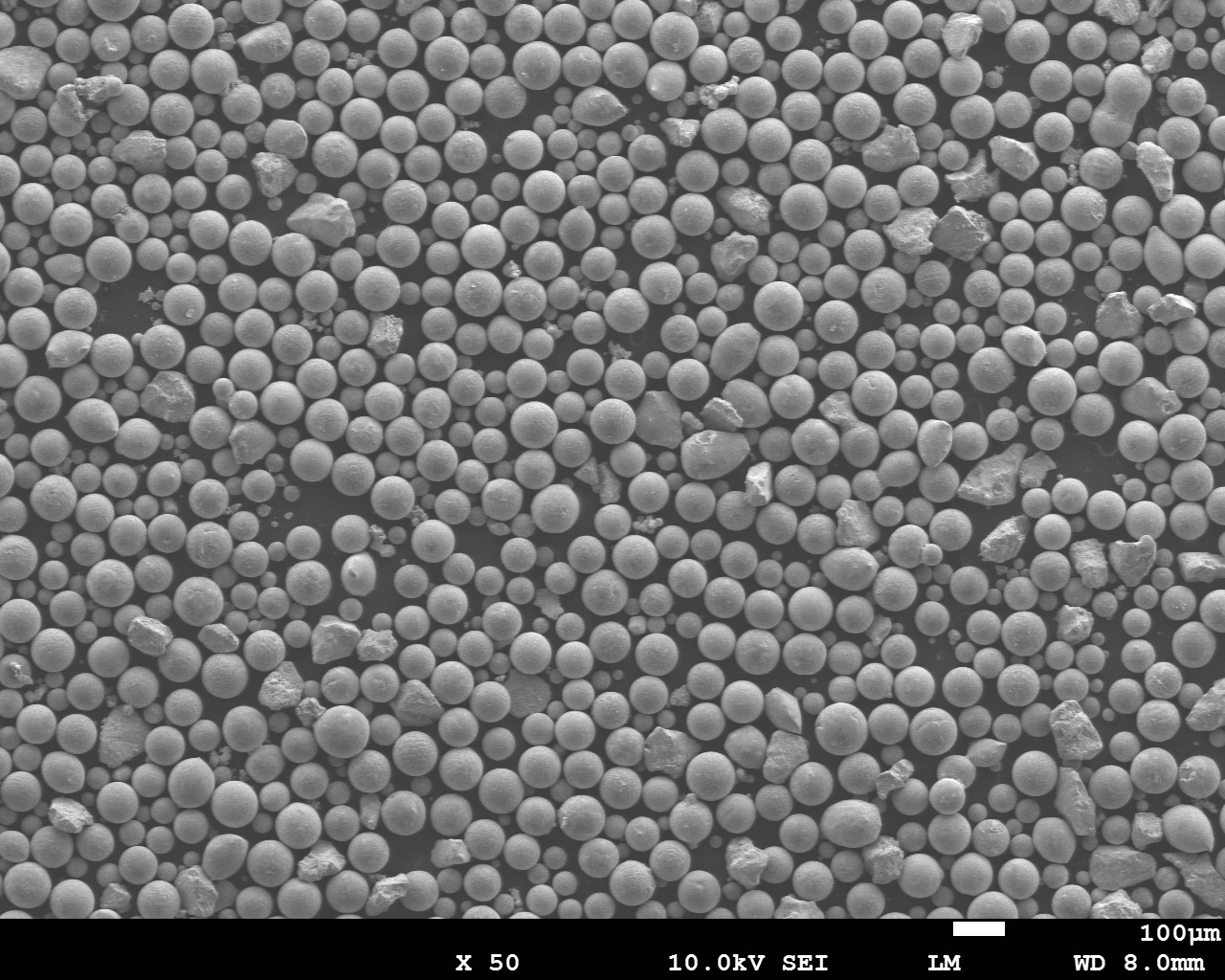

(Summary description)Spherical vanadium powder is one of the most important candidate structural materials for nuclear fusion reactors. Therefore, metallic vanadium has broad application prospects in the structural design of the first wall, cladding and divertor of fusion reactors, as well as in aerospace and high temperature fields.

What is Spherical vanadium powder

(Summary description)Spherical vanadium powder is one of the most important candidate structural materials for nuclear fusion reactors. Therefore, metallic vanadium has broad application prospects in the structural design of the first wall, cladding and divertor of fusion reactors, as well as in aerospace and high temperature fields.

- Categories:Spherical powder news

- Author:

- Origin:

- Time of issue:2021-12-15 17:32

- Views:0

Spherical vanadium powder is recognized internationally as an ideal candidate material for certain key structural components of fusion reactors. The most significant advantage is its low activation characteristics under neutron irradiation conditions and excellent high-temperature strength performance. In addition, Spherical vanadium powder also has good resistance to radiation induced expansion and damage, good dimensional stability, good thermal conductivity, low thermal expansion coefficient and elastic modulus, low biological hazard safety and environmental protection characteristics, and good Creep resistance, good processing performance, and good corrosion resistance to liquid lithium.

Spherical vanadium powder is one of the most important candidate structural materials for nuclear fusion reactors. Therefore, metallic vanadium has broad application prospects in the structural design of the first wall, cladding and divertor of fusion reactors, as well as in aerospace and high temperature fields. .

In the application of Spherical vanadium powder, it is usually necessary to make various structural parts, such as space curved shells. Because metallic vanadium will produce v2o5 at high temperatures, which is a highly toxic substance, vacuum sheath forging is usually used in the material preparation process, such as ingot billeting, extrusion, etc., if the shell is formed, this method is also used. The method, due to its large amount of deformation, has the risk of releasing toxic substances from the rupture of the sheath, and the process is relatively complicated, the margin is large, and the cost is high.

Scan the QR code to read on your phone

Top dynamic rankings

Scan the QR code and follow the official account

Products

Precious metal functional materials

High-quality optoelectronic materials/high-purity targets

Refractory metals and their alloys

Special alloy/special steel

Spherical | Nano powder

Biomedical/3D printing products

Compound

Rare metals and their alloys

Rare metals and their alloysRare Metal Concept Cultural/Art/Collectible

Nuclear energy Nuclear power Nuclear industry

High temperature heat container

Microelectronics industry Chip thermal sink

Semiconductor equipment MOCVD thermal field

High efficiency & long life Wire for wire cutting

Medical equipment Medical instruments

Artificial bone joint Bioimplantation

Rare metal cultural & creative art collection Precious metal

Plasma|Special Welding Electrode

Ultra Minor Metals Ltd (UMM) all rights reserved 湘ICP备17001881号 by:www.300.cnchangsha