Industry News

Learn more about us through the industry

News

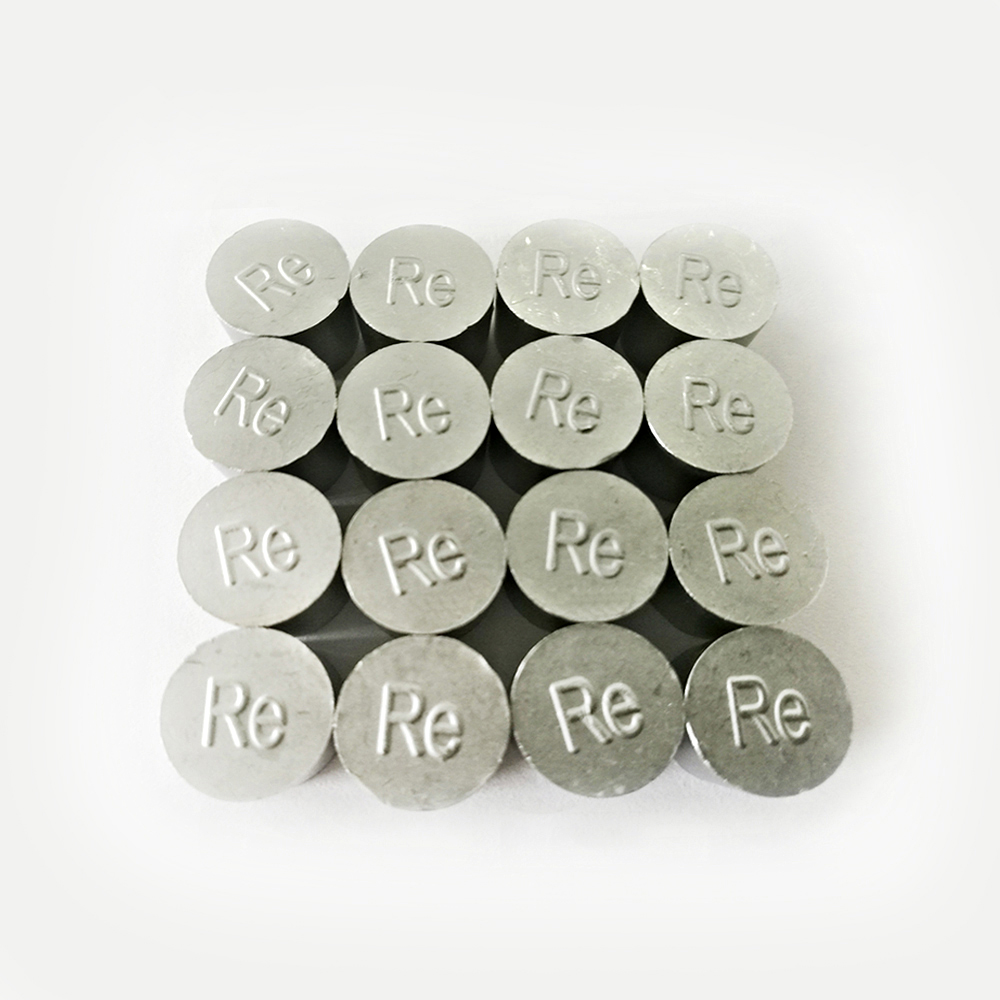

Application status and manufacturing technology of rhenium pellet

- Categories:News

- Author:

- Origin:

- Time of issue:2021-12-01 16:57

- Views:0

(Summary description)Rhenium pellet is a kind of rare refractory metal with high melting point, high strength, good plasticity and excellent mechanical stability. Its melting point is second only to tungsten, up to 3180℃.

Application status and manufacturing technology of rhenium pellet

(Summary description)Rhenium pellet is a kind of rare refractory metal with high melting point, high strength, good plasticity and excellent mechanical stability. Its melting point is second only to tungsten, up to 3180℃.

- Categories:News

- Author:

- Origin:

- Time of issue:2021-12-01 16:57

- Views:0

Rhenium pellet is a kind of rare refractory metal with high melting point, high strength, good plasticity and excellent mechanical stability. Its melting point is second only to tungsten, up to 3180℃. Rhenium has no brittle critical transition temperature. It has good creep resistance under thermal conditions and is suitable for ultra-high temperature and strong thermal shock working environment. Its room temperature tensile strength exceeds 1172 MPa, and it can still be maintained above 48 MPa at 2200°C, far exceeding other metals. Rhenium has very good thermal shock resistance at high temperatures. At a high temperature of 2200℃, engine nozzles made of rhenium can withstand 100,000 thermal fatigue cycles without failure.

In addition, rhenium pellet has very good wear resistance and corrosion resistance. Its wear resistance is second only to metal osmium. It can maintain relatively good chemical inertness for most fuels except oxygen, and will not be corroded by hot hydrogen. , The permeability to hydrogen is also very low. Because of its series of excellent properties, rhenium and its alloys are widely used in petrochemical, electronic industry, aerospace and other industries, becoming one of the most important new materials in the modern high-tech field.

The main uses of rhenium pellet are concentrated in petrochemical, aerospace, metallurgical industry, etc. How to develop new application fields is the goal of further development in the future. The preparation methods of rhenium pellet and its alloys mainly include electrochemical deposition, powder metallurgy, and electronics. Cambodia. Physical vapor deposition, chemical vapor deposition, etc., these four basic manufacturing methods have their own advantages, but in view of product requirements, performance requirements, preparation operability and manufacturing costs, chemical vapor deposition should be the ideal one. It is also the most promising manufacturing technology at present.

Scan the QR code to read on your phone

Top dynamic rankings

Scan the QR code and follow the official account

Products

Precious metal functional materials

High-quality optoelectronic materials/high-purity targets

Refractory metals and their alloys

Special alloy/special steel

Spherical | Nano powder

Biomedical/3D printing products

Compound

Rare metals and their alloys

Rare metals and their alloysRare Metal Concept Cultural/Art/Collectible

Nuclear energy Nuclear power Nuclear industry

High temperature heat container

Microelectronics industry Chip thermal sink

Semiconductor equipment MOCVD thermal field

High efficiency & long life Wire for wire cutting

Medical equipment Medical instruments

Artificial bone joint Bioimplantation

Rare metal cultural & creative art collection Precious metal

Plasma|Special Welding Electrode

Ultra Minor Metals Ltd (UMM) all rights reserved 湘ICP备17001881号 by:www.300.cnchangsha