Industry News

Learn more about us through the industry

News

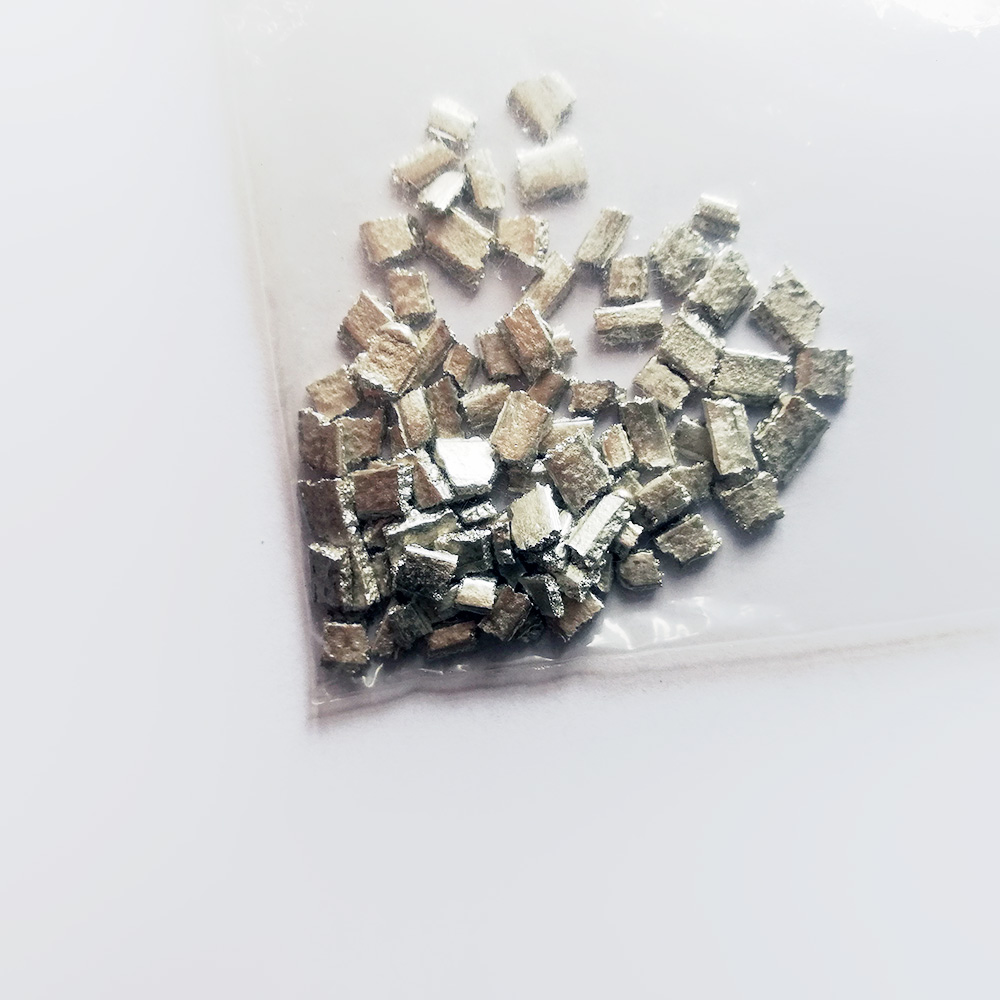

Use of Iridium ingot

- Categories:News

- Author:

- Origin:

- Time of issue:2021-08-30 09:38

- Views:0

(Summary description)Most applications of Iridium ingot use its high melting point, high hardness and corrosion resistance. Iridium ingot metal, iridium-platinum alloy and osmium-iridium alloy have very low consumption and can be used to make porous spinnerets.

Use of Iridium ingot

(Summary description)Most applications of Iridium ingot use its high melting point, high hardness and corrosion resistance. Iridium ingot metal, iridium-platinum alloy and osmium-iridium alloy have very low consumption and can be used to make porous spinnerets.

- Categories:News

- Author:

- Origin:

- Time of issue:2021-08-30 09:38

- Views:0

Most applications of Iridium ingot use its high melting point, high hardness and corrosion resistance. Iridium ingot metal, iridium-platinum alloy and osmium-iridium alloy have very low consumption and can be used to make porous spinnerets. Spinnerets are used to extrude plastic polymers into fibers, such as rayon. Osmium-iridium alloy can also be used for compass bearings and weighing scales.

Iridium ingot has strong corrosion resistance and high temperature resistance, so it is very suitable as an alloy additive. Some long-term use parts in aircraft engines are composed of iridium alloys, and iridium-titanium alloys are also used as underwater pipe materials. The addition of iridium can increase the hardness of the platinum alloy. The Vickers hardness of pure platinum is 56 HV, while the hardness of platinum alloys containing 50% iridium can exceed 500 HV.

Iridium ingot is also often used in instruments that must withstand high temperatures. For example, the Tchaikrasky method uses high-temperature crucibles made of iridium to produce single oxide crystals such as sapphire, gadolinium gallium garnet, and yttrium aluminum garnet. These crystals are used in computer memory and solid-state laser parts. Iridium alloy can resist arc erosion, so it is an ideal material for spark plug electrical contacts.

Cativa catalysis is a process of converting methanol into acetic acid, and Iridium ingot compound can be used as a catalyst.

The radioactive isotope iridium-192 is an important energy source in gamma radiography, which helps in non-destructive testing of metals. In addition, brachytherapy uses gamma rays released by Ir to treat cancer. This treatment method places the radiation source near or in the cancerous tissue, and can be used to treat prostate cancer, bile duct cancer, and cervical cancer.

Scan the QR code to read on your phone

Top dynamic rankings

2024-03-04

Scan the QR code and follow the official account

Products

Precious metal functional materials

High-quality optoelectronic materials/high-purity targets

Refractory metals and their alloys

Special alloy/special steel

Spherical | Nano powder

Biomedical/3D printing products

Compound

Rare metals and their alloys

Rare metals and their alloysRare Metal Concept Cultural/Art/Collectible

Nuclear energy Nuclear power Nuclear industry

High temperature heat container

Microelectronics industry Chip thermal sink

Semiconductor equipment MOCVD thermal field

High efficiency & long life Wire for wire cutting

Medical equipment Medical instruments

Artificial bone joint Bioimplantation

Rare metal cultural & creative art collection Precious metal

Plasma|Special Welding Electrode

Ultra Minor Metals Ltd (UMM) all rights reserved 湘ICP备17001881号 by:www.300.cnchangsha