Application Technology

Understand cutting-edge application technology

Application Technology

"Deep Sea Monster" made of titanium rhenium alloy

- Categories:Application Technology

- Author:

- Origin:

- Time of issue:2020-12-01 19:04

- Views:0

(Summary description)On April 22, 1978, the Severodvinsk Shipyard in the port city of Arkhangelsk Oblast, located in the northern part of Russia and Europe, began to build a mysterious new M-class strategic attack nuclear submarine. The boat adopts a double-layer shell structure design, and creatively adds the rarefied and refractory metal “rhenium” to the “space metal” titanium alloy to make the submarine shell. The emergence of the K278 strategic nuclear submarine once again demonstrated to the world the manufacturing capabilities of the "battle nation" in the military industry. At that time, in order to produce the world's strongest strategic nuclear submarine, the former Soviet Union did not hesitate to pay for it. It is important to know that the global annual output of metal rhenium was only one to twenty tons.

"Deep Sea Monster" made of titanium rhenium alloy

(Summary description)On April 22, 1978, the Severodvinsk Shipyard in the port city of Arkhangelsk Oblast, located in the northern part of Russia and Europe, began to build a mysterious new M-class strategic attack nuclear submarine. The boat adopts a double-layer shell structure design, and creatively adds the rarefied and refractory metal “rhenium” to the “space metal” titanium alloy to make the submarine shell. The emergence of the K278 strategic nuclear submarine once again demonstrated to the world the manufacturing capabilities of the "battle nation" in the military industry. At that time, in order to produce the world's strongest strategic nuclear submarine, the former Soviet Union did not hesitate to pay for it. It is important to know that the global annual output of metal rhenium was only one to twenty tons.

- Categories:Application Technology

- Author:

- Origin:

- Time of issue:2020-12-01 19:04

- Views:0

On April 22, 1978, the Severodvinsk Shipyard in the port city of Arkhangelsk Oblast, located in the northern part of Russia and Europe, began to build a mysterious new M-class strategic attack nuclear submarine.

Interior view of Severodvinsk shipyard

Interior view of Severodvinsk shipyard

Code name: fin

NATO code name: Mike-class

Model: 685

Navy Number: K278

Boat name: Communist Youth League member

Water displacement: 5880 tons

Submarine displacement: 8,500 tons

Water draft: 8-9 meters

Length: 117.5 meters

Overall width: 10.7 meters

Power system: 1 190 MW K-650 b-3 pressurized water reactor, 2 45,000 horsepower steam turbines

Fuel: Uranium-235

Water speed: 14 knots

Endurance: nuclear endurance

Self-sustainability: 50 days

Crew: 69 people

Weapons and equipment: 6 533mm torpedoes, equipped with 53-65/53-65k torpedoes, missile RPK-2 anti-ship missile

"Deep Sea Monster" (K278) PS image

The boat adopts a double-layer shell structure design, and creatively adds the rarefied and refractory metal “rhenium” to the “space metal” titanium alloy to make the submarine shell. The emergence of the K278 strategic nuclear submarine once again demonstrated to the world the manufacturing capabilities of the "battle nation" in the military industry. At that time, in order to produce the world's strongest strategic nuclear submarine, the former Soviet Union did not hesitate to pay for it. It is important to know that the global annual output of metal rhenium was only one to twenty tons.

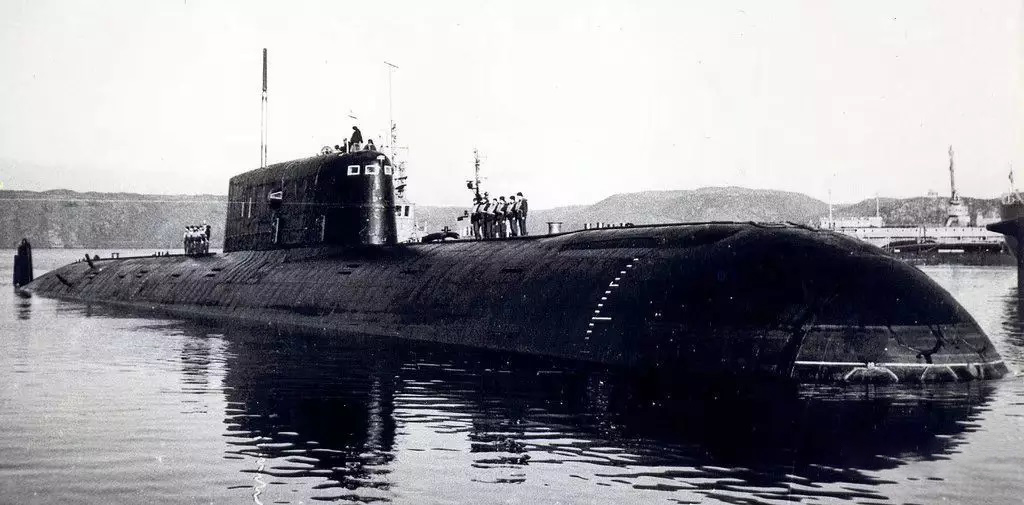

The "deep sea monster" ready to launch

This nuclear submarine can resist the huge pressure of sea water at a depth of more than 1,000 meters, which is equivalent to more than 100 standard atmospheres. The maximum maximum diving depth is an astonishing 1250 meters, while the US military deep-water torpedo at the time was only 800 meters deep.

"Deep Sea Monster" after service

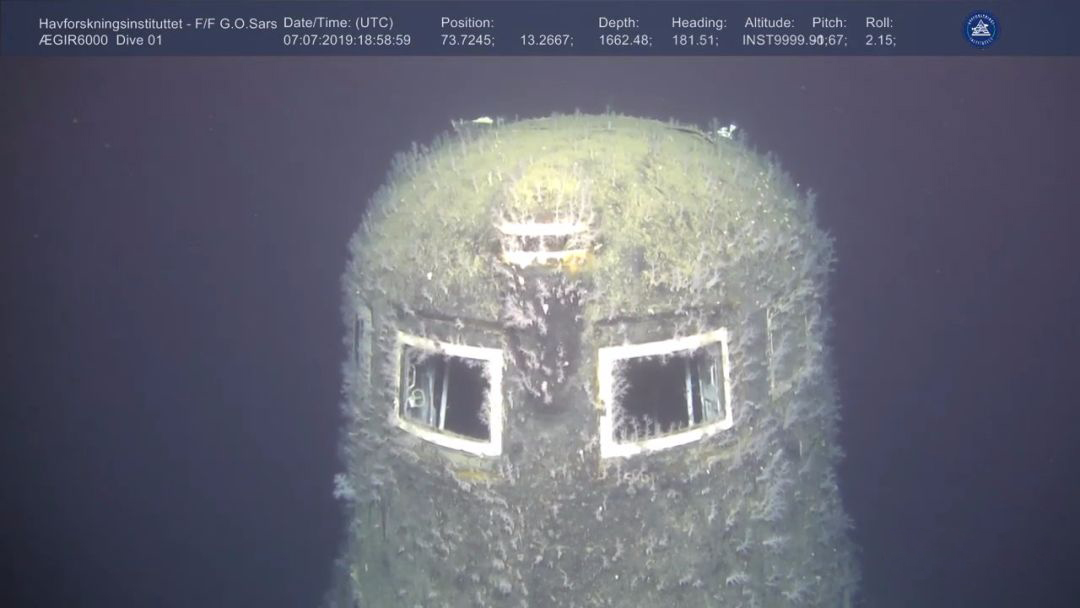

It is conceivable that such a super weapon has extremely high survivability in the deep sea. However, on April 7, 1989, after nearly 6 years of service, the submarine "Komsomol" sank due to a fire accident. The Balun Sea of the Arctic Ocean is an icy seabed of 1685 meters at 73°40ˊ north latitude and 13°30ˊ east longitude. The accident resulted in the death of 42 crew members including Captain Vanin, and 27 people were rescued. It is a pity that such a deep-sea monster has only produced one, but the world record for the deepest dive of a strategic attack nuclear submarine created by it remains to this day.

"Deep Sea Monster" after sinking

The underwater robot detects the sinking "deep sea monster"

The extreme service environment of the "deep sea monster" puts forward harsh limit requirements on many materials, among which the creative application of titanium rhenium alloy provides inspiration for future materials science experts. The light weight, high strength, and corrosion resistance of the metal "titanium", and the super strengthening effect of the battle metal "rhenium" added to the alloy, the term "like a tiger with wings" to describe this new material cannot be more beautiful. It is believed that in many other fields of science and technology in the future, such as low-altitude aircraft, super high-speed rail, aviation, aerospace, deep-sea exploration, etc., titanium rhenium alloy will receive more and more attention and development and application.

Scan the QR code to read on your phone

Hot Technology Ranking

2022-10-20

Scan the QR code and follow the official account

Products

Precious metal functional materials

High-quality optoelectronic materials/high-purity targets

Refractory metals and their alloys

Special alloy/special steel

Spherical | Nano powder

Biomedical/3D printing products

Compound

Rare metals and their alloys

Rare metals and their alloysRare Metal Concept Cultural/Art/Collectible

Nuclear energy Nuclear power Nuclear industry

High temperature heat container

Microelectronics industry Chip thermal sink

Semiconductor equipment MOCVD thermal field

High efficiency & long life Wire for wire cutting

Medical equipment Medical instruments

Artificial bone joint Bioimplantation

Rare metal cultural & creative art collection Precious metal

Plasma|Special Welding Electrode

Ultra Minor Metals Ltd (UMM) all rights reserved 湘ICP备17001881号 by:www.300.cnchangsha