Industry News

Learn more about us through the industry

News

The main purpose of Os sputtering target

- Categories:osmium target news

- Author:

- Origin:

- Time of issue:2023-01-12 16:49

- Views:0

(Summary description)Os sputtering target is the main raw material for the preparation of electronic thin film materials by physical vapor deposition (PVD), which is mainly composed of target blanks, back plates and other parts.

The main purpose of Os sputtering target

(Summary description)Os sputtering target is the main raw material for the preparation of electronic thin film materials by physical vapor deposition (PVD), which is mainly composed of target blanks, back plates and other parts.

- Categories:osmium target news

- Author:

- Origin:

- Time of issue:2023-01-12 16:49

- Views:0

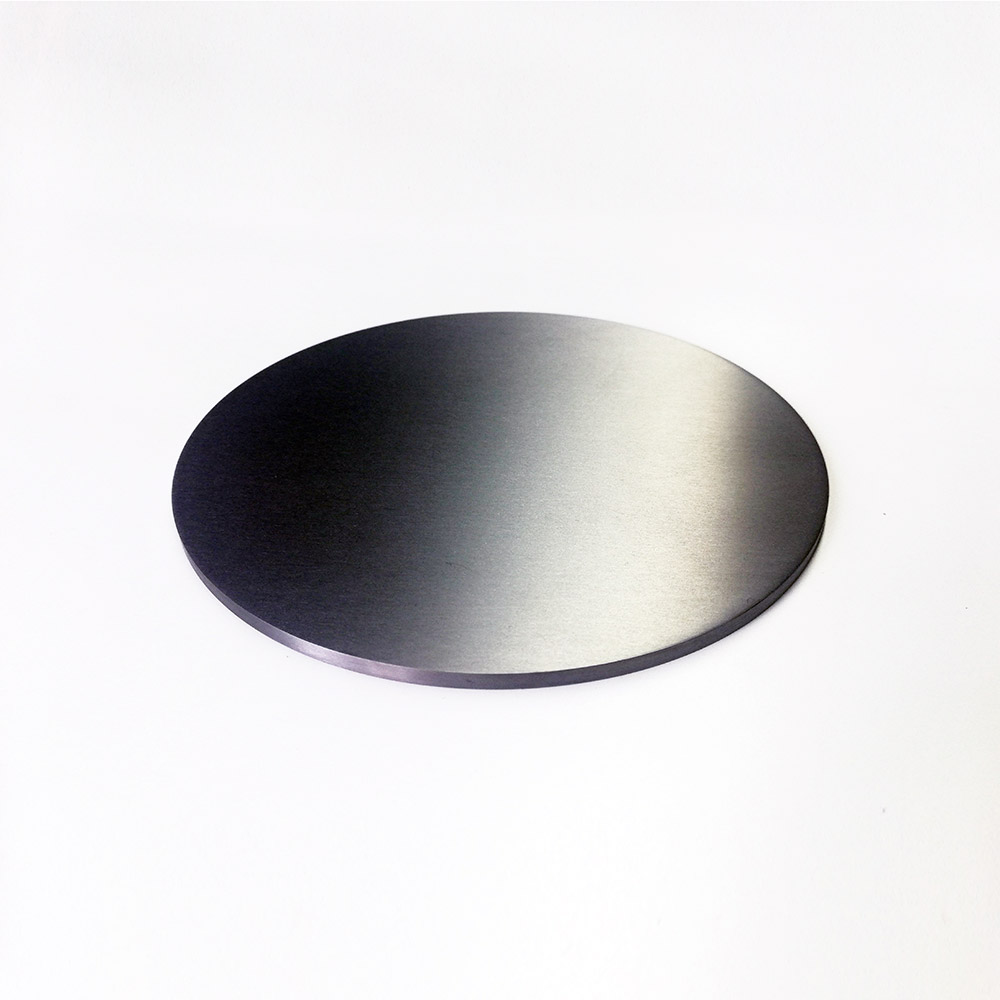

Os sputtering target is the main raw material for the preparation of electronic thin film materials by physical vapor deposition (PVD), which is mainly composed of target blanks, back plates and other parts. Among them, the target blank is the target material bombarded by the high-speed ion flow after preparation, and its surface atoms are scattered out after being bombarded to form a thin film material; while the back plate has good conductivity and thermal conductivity, which mainly plays a role in fixing the sputtering during the bombardment process. The role of shooting targets.

There are many types of Os sputtering target materials, which can be divided into long targets, square targets, and round targets according to their shapes; metal targets (pure metal aluminum, titanium, copper, tantalum, etc.), alloy targets (nickel-chromium, etc.) Alloys, nickel-cobalt alloys, etc.), ceramic compound targets (oxides, silicides, carbides, sulfides, etc.). It has a wide range of application fields, and there are certain differences in material selection and performance requirements for sputtering targets in different application fields. The details are as follows:

Targets commonly used in semiconductor chips are ultra-high-purity aluminum targets, titanium targets, copper targets, tantalum targets, etc., which are mainly used to prepare key raw materials for integrated circuits, with the highest technical requirements in terms of performance, ultra-high-purity metals, and high-precision size, high integration;

The targets commonly used in flat panel displays are high-purity aluminum targets, copper targets, molybdenum targets, tin-doped indium oxide (ITO targets), etc., which are mainly used in high-definition TVs, notebook computers, etc., and have high technical requirements in terms of performance. High-purity materials, large material area, high uniformity and fineness;

The targets commonly used in solar cells are high-purity aluminum targets, copper targets, molybdenum targets, chromium targets, ITO targets, etc., which are mainly used in thin-film solar cells, with high technical requirements in terms of performance and a wide range of applications;

Commonly used targets for information storage are chromium-based targets, cobalt-based alloy targets, etc., which are mainly used in optical drives, optical discs, etc., with high storage density and high transmission speed in terms of performance;

Commonly used targets for tool modification are pure metal chromium targets, chromium-aluminum alloy targets, etc., which are mainly used in surface strengthening of tools and molds, with high performance requirements and extended service life;

Nickel-chromium alloy targets, chromium-silicon alloy targets, etc., which are commonly used in electronic devices, are mainly used in thin film resistors and thin film capacitors. The performance requirements of electronic devices are small in size, good in stability, and small in temperature coefficient of resistance;

The targets used in other fields are pure metal chromium targets, titanium targets, nickel targets, etc., which are mainly used in decorative coatings, glass coatings, etc., with general performance and technical requirements.

Scan the QR code to read on your phone

Top dynamic rankings

2024-03-04

Scan the QR code and follow the official account

Products

Precious metal functional materials

High-quality optoelectronic materials/high-purity targets

Refractory metals and their alloys

Special alloy/special steel

Spherical | Nano powder

Biomedical/3D printing products

Compound

Rare metals and their alloys

Rare metals and their alloysRare Metal Concept Cultural/Art/Collectible

Nuclear energy Nuclear power Nuclear industry

High temperature heat container

Microelectronics industry Chip thermal sink

Semiconductor equipment MOCVD thermal field

High efficiency & long life Wire for wire cutting

Medical equipment Medical instruments

Artificial bone joint Bioimplantation

Rare metal cultural & creative art collection Precious metal

Plasma|Special Welding Electrode

Ultra Minor Metals Ltd (UMM) all rights reserved 湘ICP备17001881号 by:www.300.cnchangsha