Industry News

Learn more about us through the industry

News

Development background of spherical chromium powder

- Categories:Spherical powder news

- Author:

- Origin:

- Time of issue:2022-11-23 14:35

- Views:0

(Summary description)In recent years, with the continuous development of 3D printing technology, the field of powder metallurgy has attracted more and more attention.

Development background of spherical chromium powder

(Summary description)In recent years, with the continuous development of 3D printing technology, the field of powder metallurgy has attracted more and more attention.

- Categories:Spherical powder news

- Author:

- Origin:

- Time of issue:2022-11-23 14:35

- Views:0

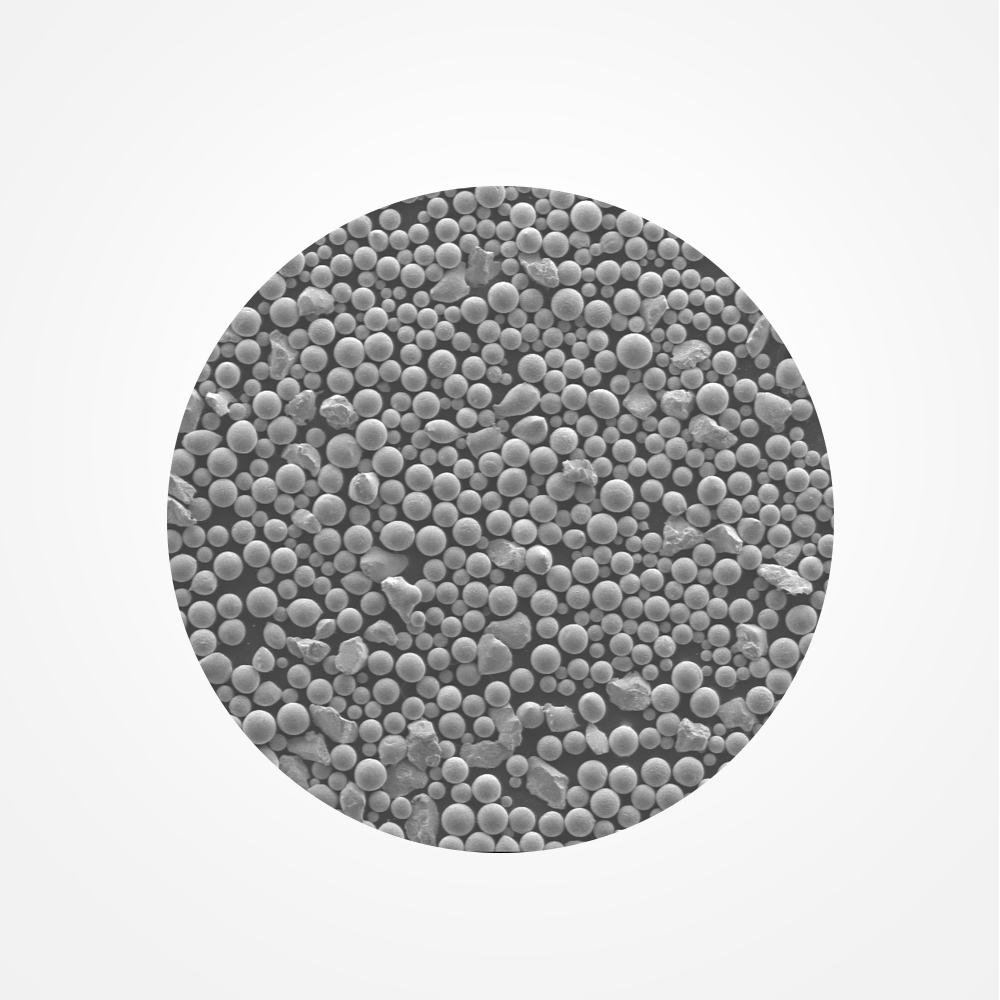

In recent years, with the continuous development of 3D printing technology, the field of powder metallurgy has attracted more and more attention. Metal chromium is often used in metallurgy, chemical industry, electroplating, pharmaceutical and other industries due to its good chemical stability, high temperature resistance and corrosion resistance. At present, the chromium powder produced by the conventional powder-making technology is generally irregular in shape, resulting in the disadvantages of poor fluidity of the chromium powder and low density of the powder product. In order to improve the fluidity of the powder, a spherical chromium powder was prepared.

At present, there are radio frequency plasma methods for producing spherical chromium powder at home and abroad. Radio frequency plasma has the advantages of high energy density, high heating intensity, large volume of plasma torch, and simple process for processing materials. Irregular chromium powder particles of raw materials are sprayed into the plasma torch by carrying gas through the feeding gun, and are rapidly heated and melted to form highly spherical droplets, which are rapidly solidified in a very short period of time to form spherical chromium powder. However, the chromium powder prepared by the plasma method has good sphericity, but the gas content is difficult to control. The cost of this method is high, and it is impossible to prepare fine powder with a particle size of less than 45 μm due to the limitation of the feeding method.

Scan the QR code to read on your phone

Top dynamic rankings

2024-03-04

Scan the QR code and follow the official account

Products

Precious metal functional materials

High-quality optoelectronic materials/high-purity targets

Refractory metals and their alloys

Special alloy/special steel

Spherical | Nano powder

Biomedical/3D printing products

Compound

Rare metals and their alloys

Rare metals and their alloysRare Metal Concept Cultural/Art/Collectible

Nuclear energy Nuclear power Nuclear industry

High temperature heat container

Microelectronics industry Chip thermal sink

Semiconductor equipment MOCVD thermal field

High efficiency & long life Wire for wire cutting

Medical equipment Medical instruments

Artificial bone joint Bioimplantation

Rare metal cultural & creative art collection Precious metal

Plasma|Special Welding Electrode

Ultra Minor Metals Ltd (UMM) all rights reserved 湘ICP备17001881号 by:www.300.cnchangsha