Application Technology

Understand cutting-edge application technology

Application Technology

CT machine X-ray tube anode rotating target

- Categories:Application Technology

- Author:

- Origin:

- Time of issue:2020-12-11 11:42

- Views:0

(Summary description)When the CT tube is working, the anode target produces X-rays under the bombardment of high-energy electron beams, but the energy conversion efficiency is very low. Only about 1% of the energy is converted into X-ray energy, and the remaining 99% of the energy is converted into heat energy. The local temperature can be as high as 2600°C. Therefore, the rotating anode target needs to have the characteristics of high high temperature strength, good thermal shock resistance, and fast heat dissipation. Therefore, the density of the target material, the content of alloy impurity elements, and the brazing bonding strength of graphite and molybdenum alloys affect the service life of the target. Key factor.

CT machine X-ray tube anode rotating target

(Summary description)When the CT tube is working, the anode target produces X-rays under the bombardment of high-energy electron beams, but the energy conversion efficiency is very low. Only about 1% of the energy is converted into X-ray energy, and the remaining 99% of the energy is converted into heat energy. The local temperature can be as high as 2600°C. Therefore, the rotating anode target needs to have the characteristics of high high temperature strength, good thermal shock resistance, and fast heat dissipation. Therefore, the density of the target material, the content of alloy impurity elements, and the brazing bonding strength of graphite and molybdenum alloys affect the service life of the target. Key factor.

- Categories:Application Technology

- Author:

- Origin:

- Time of issue:2020-12-11 11:42

- Views:0

CT (Computed Tomography), that is, electronic computer tomography. CT machine is an imaging instrument that applies CT imaging technology and is widely used in clinical medicine. It has significant advantages in displaying anatomical shape, structure and density. CT imaging is based on the premise of not destroying the structure of the object. According to the projection data of a certain physical quantity (such as X-ray light intensity, wave speed, electron beam intensity, etc.) obtained around the object, reconstruct the two-dimensional object on a specific level. Image, and build a three-dimensional image based on the above-mentioned two-dimensional image technology. CT machines have been widely used in many fields such as medicine, industry, engineering, agriculture, safety inspection and other industries.

CT equipment mainly has the following three parts:

Scanning part: consists of X-ray tube, detector and scanning frame;

Computer system: store and calculate the information and data collected by scanning;

Image display and storage system: display the image processed and reconstructed by the computer on the TV screen or take the image with multiple cameras or laser cameras.

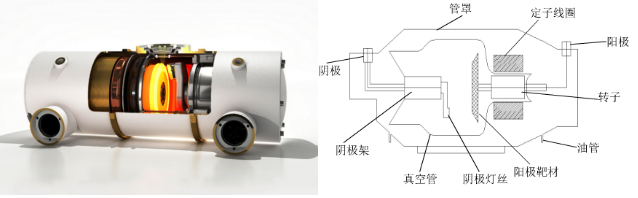

The X-ray generator is the key component of CT equipment. The vacuum tube in the tube cover is the rotating anode ray tube, and its inner parts include anode, cathode, filament and rotor.

The anode target, as a necessary part of the X-ray generator, can be divided into fixed type and rotating type according to the anode structure and working environment. The fixed anode is composed of a target material, an anode body, etc. When the focused electron beam generated by the cathode irradiates a point on the anode, X-rays are generated, and high heat is generated at the same time, which is usually a vulnerable part that needs to be replaced regularly . Compared with the fixed anode target, the rotating anode target is mainly composed of the anode target, the rotor, the rotor shaft, the anode shaft, etc. When the electron beam irradiates the anode target material, the continuously rotating anode can effectively prevent itself from being burned by the electron beam. And it can continuously provide a new target surface to be irradiated, which not only increases the utilization rate of the anode target material, increases the heat dissipation area of the target surface, but also greatly improves the power of the X-ray tube, and can be used for a long time without interruption. According to the material of the anode target, the X-ray anode target can also be divided into pure metal target and composite target, such as pure metal tungsten target, which has the advantages of high melting point, low vapor pressure, high density and high atomic number, which can guarantee the impact of electron beam A large number of X-rays are generated, but pure tungsten has a small heat capacity and poor heat dissipation performance, and is prone to microcracks that cause damage to the anode target. Commonly used medical high-performance composite targets include tungsten rhenium/TZM, tungsten molybdenum/graphite, tungsten rhenium/graphite and other composite targets. The composite target can not only reduce the weight of the overall target material, reduce the volume, but also increase the heat dissipation efficiency and sufficient Give play to the excellent performance of each composite layer.

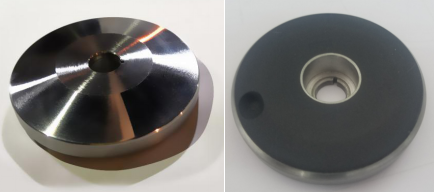

When the CT tube is working, the anode target produces X-rays under the bombardment of high-energy electron beams, but the energy conversion efficiency is very low. Only about 1% of the energy is converted into X-ray energy, and the remaining 99% of the energy is converted into heat energy. The local temperature can be as high as 2600°C. Therefore, the rotating anode target needs to have the characteristics of high high temperature strength, good thermal shock resistance, and fast heat dissipation. Therefore, the density of the target material, the content of alloy impurity elements, and the brazing bonding strength of graphite and molybdenum alloys affect the service life of the target. Key factor.

In order to increase the anode power, the following technical measures are also taken:

1.Blackening of the anode target disk: After the anode target disk is blackened, its thermal emissivity is close to 1, and the heat emitted at the same target temperature is doubled compared with the unblackened target disk, thereby increasing the perspective power and shortening Cooling time, speed up the single film and series of photography process;

2.Using graphite target base: graphite has a specific heat about 10 times greater than tungsten, an emissivity close to 1, and a heat transmission coefficient similar to tungsten and molybdenum, so it is more suitable for use as a target base;

3.High-speed rotating anode: The anode speed of the rotating anode X-ray tube reaches 2800r/min. The high rotation speed can make the electron beam stay at a certain point for a short time, and the target can withstand more power;

4.Increase the diameter of the anode target: the larger the anode target diameter, the greater the capacity and the faster the heat dissipation speed. However, due to the difficulties caused by mechanical strength and dynamic balance, the increase in diameter is limited. At present, the anode target diameter of high-power CT machine has increased from 75-80mm to about 100-150mm;

5.Eliminate the thermal stress of the rotating anode: the anode material uses tungsten and molybdenum, which is characterized by low temperature brittleness. The X-ray tube in the cooling state is suddenly loaded with a large load, and the temperature of the area bombarded by the electron beam increases, which is very different from the surrounding area. The temperature difference causes thermal stress, which can easily cause cracks and damage to the target surface. For this reason, several radial slits are opened on the anode target, so that the anode target can expand and contract when the temperature rises, and avoid damage due to excessive stress;

6.Reduce the anode tilt angle α (short-time exposure): Since the power P≈1/sinα, reducing the anode tilt angle can not only improve the image definition, but also increase the instantaneous power. However, due to the reduction of the inclination angle, the corresponding irradiation surface has also been reduced, so it cannot be selected too small. Currently, it is generally between 6-17.5°.

Scan the QR code to read on your phone

Hot Technology Ranking

2022-10-20

Scan the QR code and follow the official account

Products

Precious metal functional materials

High-quality optoelectronic materials/high-purity targets

Refractory metals and their alloys

Special alloy/special steel

Spherical | Nano powder

Biomedical/3D printing products

Compound

Rare metals and their alloys

Rare metals and their alloysRare Metal Concept Cultural/Art/Collectible

Nuclear energy Nuclear power Nuclear industry

High temperature heat container

Microelectronics industry Chip thermal sink

Semiconductor equipment MOCVD thermal field

High efficiency & long life Wire for wire cutting

Medical equipment Medical instruments

Artificial bone joint Bioimplantation

Rare metal cultural & creative art collection Precious metal

Plasma|Special Welding Electrode

Ultra Minor Metals Ltd (UMM) all rights reserved 湘ICP备17001881号 by:www.300.cnchangsha