Application Technology

Understand cutting-edge application technology

Application Technology

MOCVD irreplaceable "rhenium" heater member

- Categories:Application Technology

- Author:

- Origin:

- Time of issue:2020-12-11 11:35

- Views:0

(Summary description)Tungsten heating devices will become brittle after being recrystallized after being used at high temperature, and will easily break under impact or vibration. Compared with tungsten, rhenium has a higher recrystallization temperature, and the recrystallized rhenium is not a brittle material, but its strength is reduced. As a non-stressed heating device, it still has good working ability and has the best high temperature stability. High creep strength. Therefore, rhenium is used to manufacture MOCVD heating devices. It is the most appropriate choice in consideration of performance and cost. No other material can replace it.

MOCVD irreplaceable "rhenium" heater member

(Summary description)Tungsten heating devices will become brittle after being recrystallized after being used at high temperature, and will easily break under impact or vibration. Compared with tungsten, rhenium has a higher recrystallization temperature, and the recrystallized rhenium is not a brittle material, but its strength is reduced. As a non-stressed heating device, it still has good working ability and has the best high temperature stability. High creep strength. Therefore, rhenium is used to manufacture MOCVD heating devices. It is the most appropriate choice in consideration of performance and cost. No other material can replace it.

- Categories:Application Technology

- Author:

- Origin:

- Time of issue:2020-12-11 11:35

- Views:0

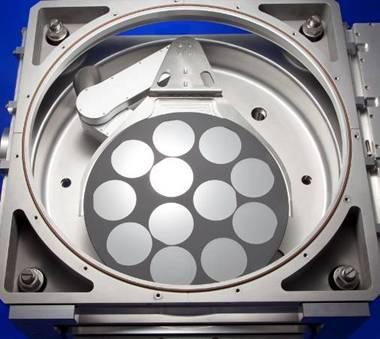

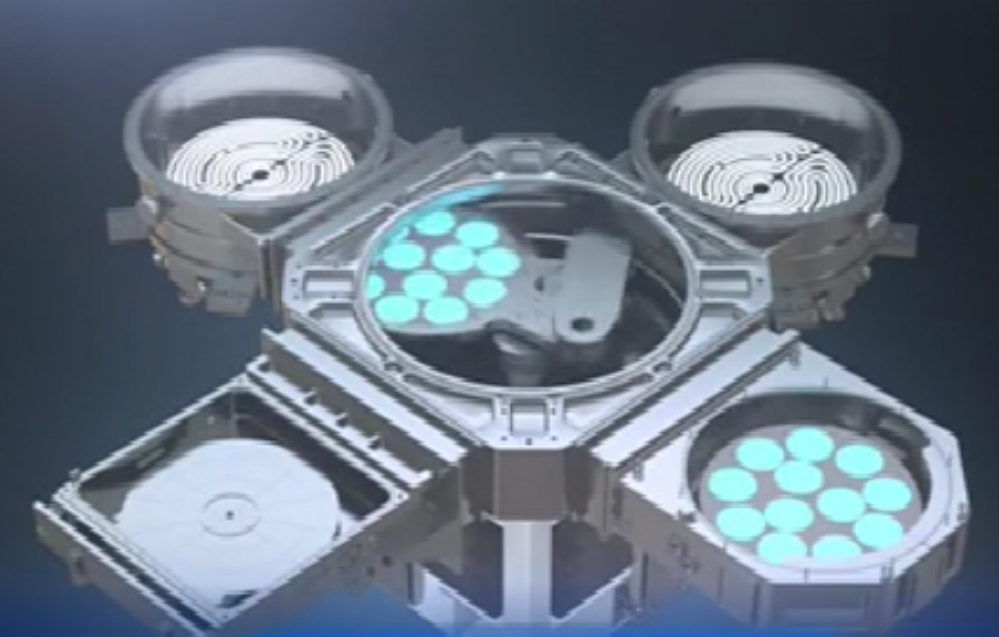

Metal Organic Chemical Vapor Deposition (MOCVD) is a chip epitaxial technology for preparing mixed semiconductor devices, metal and metal oxide and metal nitride film materials. In the MOCVD system, crystal growth is mostly under normal pressure or low pressure (10-100 Torr), and the substrate temperature is 500 to 1200 ℃. In order to grow pure, steep interface, and good uniform film materials, MOCVD equipment needs to be chemical The reaction provides a suitable environment. The heating system is an important part of the MOCVD equipment. Whether it can heat the substrate quickly and uniformly directly affects the quality of film deposition, thickness consistency, and chip performance.

The working conditions of the MOCVD heater are very harsh: long continuous working time, high temperature, high heat flux and repeated temperature rise and fall. The resistor piece is the core part of the heater. After a certain current is passed, the resistor piece generates heat and becomes the heat source of the entire device. When the surface temperature of the graphite plate used to place the substrate is 1350K, the temperature of the resistance piece is as high as 2000K, and the temperature of the resistance heater can reach 2500℃ or more during the heating process, so the selected material must have high melting point, good high temperature strength, and chemical High stability characteristics. Take the MOCVD equipment for growing GaN as an example, the optimal growth temperature is about 1000~1200℃. The temperature of the heating element of the heater is about 1500~2000℃. In the process of growing GaN, the epitaxial substrate is required to rapidly rise in temperature (the heating rate reaches 3-10°C/s) and drop in temperature.

According to the process requirements of the MOCVD equipment, the performance of the heating ring must meet: 1. Realize uniform heating of the large-size graphite tray, and the effective area ratio should cover the entire surface as much as possible; 2. The temperature rise and fall rate is fast and the stability time is short; 3. The temperature rise and fall dynamics Keep the temperature uniform during the process; 4. For different gas flow environments, uniform heating can be achieved; 5. In the process of repeated heating and cooling, the structure is stable and reliable, and the service life is long.

According to the working characteristics of MOCVD, the selection of metal resistance heating elements is the most reasonable. According to the actual temperature conditions that need to be met, only a few refractory metals such as tungsten and rhenium can meet the requirements of use.

| Performance name | Pure tungsten | Pure rhenium | |

|

Melting point/℃ |

3410 |

3170 |

|

|

Density/(g/cm3) |

19.3 |

21.02 |

|

|

Resistivity μΩ·cm |

20℃ |

5.5 |

19.8 |

|

1000℃ |

36.2 |

62 |

|

|

1500℃ |

52 |

82 |

|

|

2000℃ |

66 |

150 |

|

|

Microhardness/MPa |

Processing state |

3423-3923 |

4903-7845 |

|

1000℃ annealing |

834 |

2256-2452 |

|

|

Tensile strength/MPa |

Processing state |

1950 |

1600 |

|

1400℃ annealing |

1650 |

1400 |

|

|

1600℃ annealing |

1200 |

1400 |

|

|

1800℃ annealing |

850 |

1400 |

|

|

Elongation/% |

Processing state |

1-2 |

1-2 |

|

1400℃ annealing |

1-2 |

20-25 |

|

|

1600℃ annealing |

1-2 |

18-20 |

|

|

1800℃ annealing |

1-2 |

10-15 |

|

| Recrystallization temperature |

1100℃ |

1500℃ |

|

Tungsten heating devices will become brittle after being recrystallized after being used at high temperature, and will easily break under impact or vibration. Compared with tungsten, rhenium has a higher recrystallization temperature, and the recrystallized rhenium is not a brittle material, but its strength is reduced. As a non-stressed heating device, it still has good working ability and has the best high temperature stability. High creep strength. Therefore, rhenium is used to manufacture MOCVD heating devices. It is the most appropriate choice in consideration of performance and cost. No other material can replace it.

Scan the QR code to read on your phone

Hot Technology Ranking

2022-10-20

Scan the QR code and follow the official account

Products

Precious metal functional materials

High-quality optoelectronic materials/high-purity targets

Refractory metals and their alloys

Special alloy/special steel

Spherical | Nano powder

Biomedical/3D printing products

Compound

Rare metals and their alloys

Rare metals and their alloysRare Metal Concept Cultural/Art/Collectible

Nuclear energy Nuclear power Nuclear industry

High temperature heat container

Microelectronics industry Chip thermal sink

Semiconductor equipment MOCVD thermal field

High efficiency & long life Wire for wire cutting

Medical equipment Medical instruments

Artificial bone joint Bioimplantation

Rare metal cultural & creative art collection Precious metal

Plasma|Special Welding Electrode

Ultra Minor Metals Ltd (UMM) all rights reserved 湘ICP备17001881号 by:www.300.cnchangsha