Industry News

Learn more about us through the industry

News

Osmium ingot manufacturers explain the distribution of osmium deposits

- Categories:osmium target news

- Author:

- Origin:

- Time of issue:2022-09-21 15:39

- Views:0

(Summary description)Osmium is a platinum group element, which exists almost completely in elemental state and is highly dispersed in various ores.

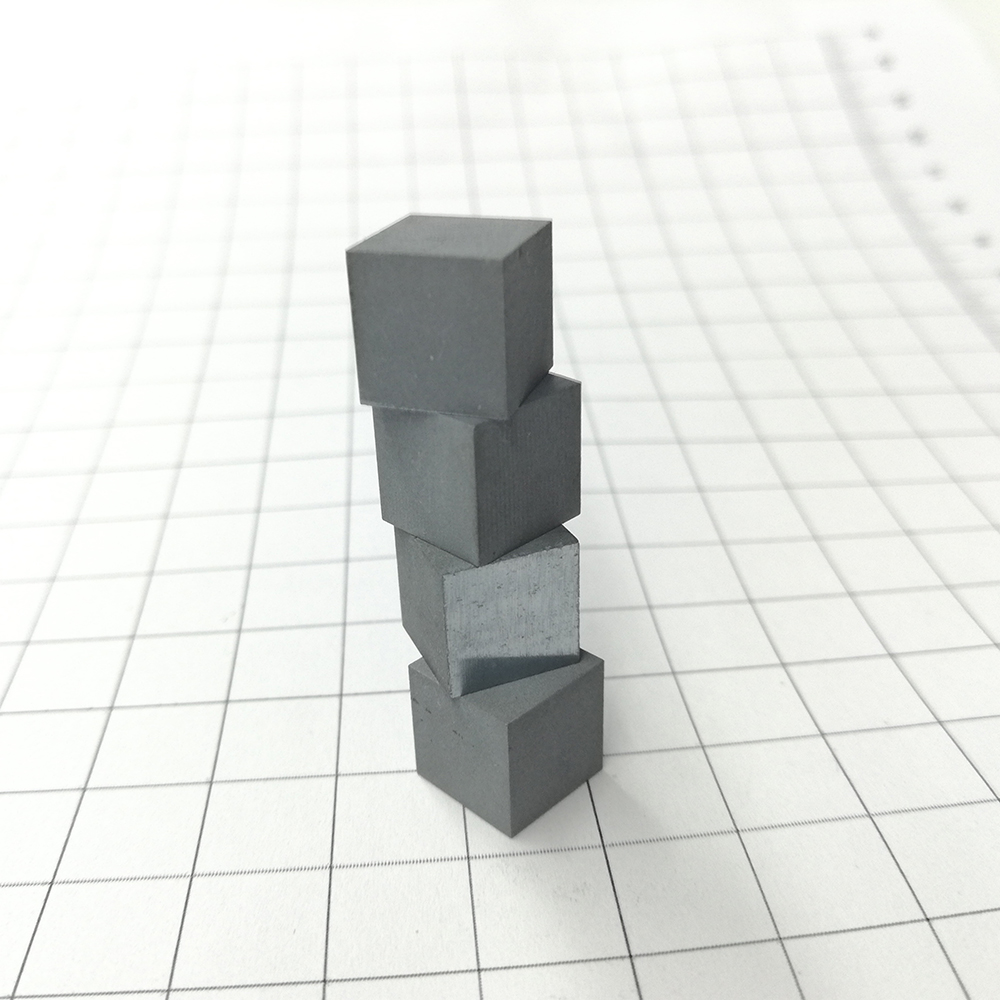

Osmium ingot manufacturers explain the distribution of osmium deposits

(Summary description)Osmium is a platinum group element, which exists almost completely in elemental state and is highly dispersed in various ores.

- Categories:osmium target news

- Author:

- Origin:

- Time of issue:2022-09-21 15:39

- Views:0

Osmium is a platinum group element, which exists almost completely in elemental state and is highly dispersed in various ores. For example, the original platinum ore, nickel-copper sulfide ore, magnetite and so on. Platinum group elements co-exist almost without exception to form natural alloys. In ores containing platinum group elements, platinum is usually the main component, while the rest of the platinum group elements must be found through chemical analysis due to their small content. Since osmium, iridium, palladium, rhodium, and ruthenium all form ores together with platinum, they are all found in the residues after platinum extraction from platinum ores. The platinum group elements are chemically stable. In addition to platinum and palladium, they are not only insoluble in common acids, but also in aqua regia. Platinum is very soluble in aqua regia, and palladium is also soluble in hot nitric acid. All platinum group elements have a strong tendency to form coordination compounds.

Osmium can be used as a catalyst in industry. When osmium is used as a catalyst for ammonia synthesis or hydrogenation, higher conversions can be obtained at not too high temperatures. If a little osmium is mixed into platinum, it can be made into a hard and sharp osmium-platinum alloy scalpel.

Scan the QR code to read on your phone

Top dynamic rankings

Scan the QR code and follow the official account

Products

Precious metal functional materials

High-quality optoelectronic materials/high-purity targets

Refractory metals and their alloys

Special alloy/special steel

Spherical | Nano powder

Biomedical/3D printing products

Compound

Rare metals and their alloys

Rare metals and their alloysRare Metal Concept Cultural/Art/Collectible

Nuclear energy Nuclear power Nuclear industry

High temperature heat container

Microelectronics industry Chip thermal sink

Semiconductor equipment MOCVD thermal field

High efficiency & long life Wire for wire cutting

Medical equipment Medical instruments

Artificial bone joint Bioimplantation

Rare metal cultural & creative art collection Precious metal

Plasma|Special Welding Electrode

Ultra Minor Metals Ltd (UMM) all rights reserved 湘ICP备17001881号 by:www.300.cnchangsha