Products Center

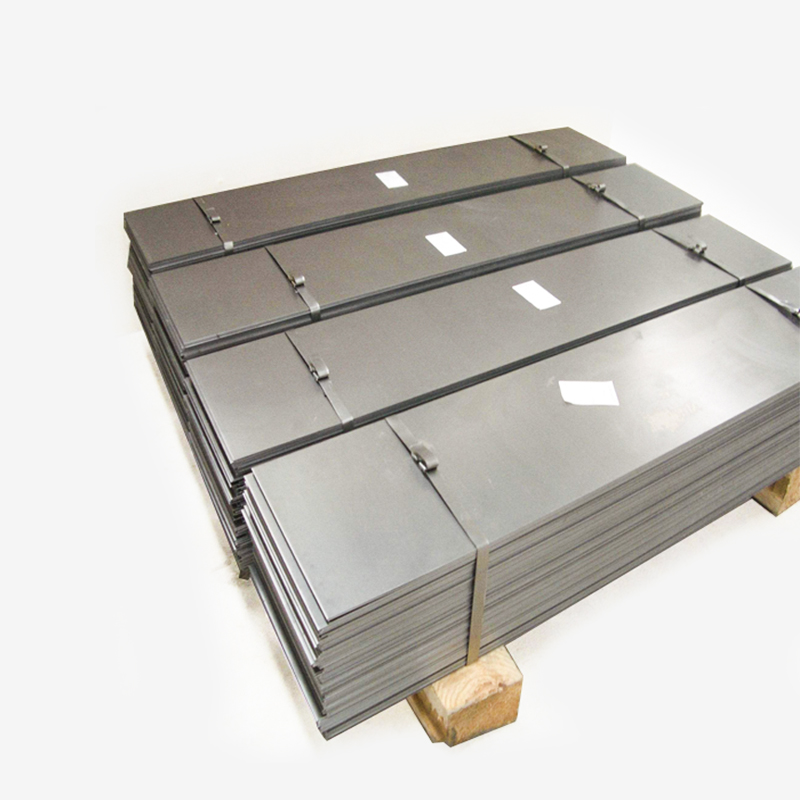

Top ten high-end specialty thin material products

Products

2. Brands: Hastelloy x, Hastelloy R-135, Nimonic 80A, Nimonic 90, Incoloy901, Incoloy903, Inconel718, Inconel x-750, Udimet500, etc.

1. Deformed superalloy refers to a type of metal material based on iron, nickel, and cobalt that can resist oxidation or corrosion in a high temperature environment above 600 ℃, and can work for a long time under a certain stress.

2. Brands: Hastelloy x, Hastelloy R-135, Nimonic 80A, Nimonic 90, Incoloy901, Incoloy903, Inconel718, Inconel x-750, Udimet500, etc.

| Series Brand | Foreign brand | China brand | Product use | Application | Specification | Guideline |

| Hastelloy Series | Hastelloy x | GH3536 | Combustion chamber below 1050℃ | Mainly used in the manufacture of high temperature components such as turbine blades, guide blades, turbine disks, high-pressure compressor disks and combustion chambers of aviation, naval and industrial gas turbines, and also used in the manufacture of aerospace vehicles, rocket engines, nuclear reactors, petrochemical equipment and coal Energy conversion devices such as conversion. The oxidation resistance temperature can reach 900℃-1250℃, which is suitable for various combustion chamber and heat exchanger materials. It has high-temperature endurance strength in the range of 700℃-1000℃, suitable for shafts, discs and blades of gas turbines. As well as connectors, bolts and fasteners. | Rods, tubes, plates, wires, forgings, rings | GB/T14992 superalloy grades, GB/T14993 superalloy hot-rolled bars, GB/T14994 superalloy cold drawn rods, GB/T 15062 general-purpose superalloy pipes, YB/T5247 superalloy welding wire, YB/T5249 superalloy cold heading wire |

| Hastelloy R-135 | GH4163 | Turbine discs and parts below 950℃ | ||||

| Nimonic series | Nimonic 80A | GH4080A | Turbine blades below 900℃ | |||

| Nimonic 90 | GH4090 | Turbine blades below 950℃ | ||||

| Incoloy Series | Incoloy901 | GH2901 | Fasteners below 700℃ | |||

| Incoloy903 | GH2903 | Fasteners below 750℃ | ||||

| Inconel series | Inconel718 | GH4169 | Turbine blades below 968℃ | |||

| Inconel x-750 | GH4145 | Turbine blades below 900℃ | ||||

| Udimet series | Udimet500 | GH4500 | Turbine blades below 900℃ | |||

| A286 | GH2132 | 650-700 turbine discs, ring parts, stamping parts | ||||

| Iron-based series | GH1131 | Used for high temperature static load below 900℃, dynamic load below 700℃. | ||||

| GH2302 | Used in combustion chambers below 800°C and fastening couplings below 650°C. | |||||

| Nickel-based series | GH3044 | Used in 800℃-950℃ turbine engine combustion chamber, afterburner and other parts. | ||||

| Gh4049 | Used in 800℃-900℃ turbine engine combustion chambers, gas blades and other parts. |

Everyone is watching

Products

Precious metal functional materials

High-quality optoelectronic materials/high-purity targets

Refractory metals and their alloys

Special alloy/special steel

Spherical | Nano powder

Biomedical/3D printing products

Compound

Rare metals and their alloys

Rare metals and their alloysRare Metal Concept Cultural/Art/Collectible

Nuclear energy Nuclear power Nuclear industry

High temperature heat container

Microelectronics industry Chip thermal sink

Semiconductor equipment MOCVD thermal field

High efficiency & long life Wire for wire cutting

Medical equipment Medical instruments

Artificial bone joint Bioimplantation

Rare metal cultural & creative art collection Precious metal

Plasma|Special Welding Electrode

Ultra Minor Metals Ltd (UMM) all rights reserved 湘ICP备17001881号 by:www.300.cnchangsha